Home

About us

Service

Contact us

Get A Quote

- Customer case

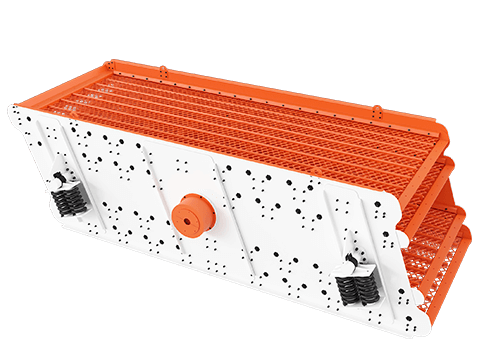

- Indonesian customers purchased our 200-ton crushing production line on site

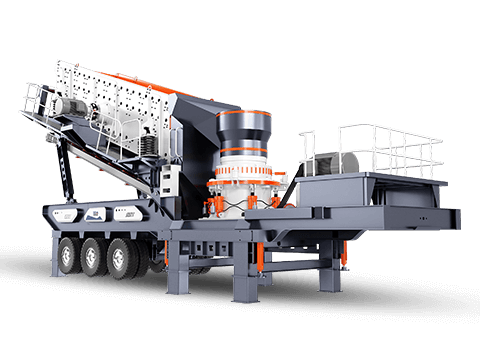

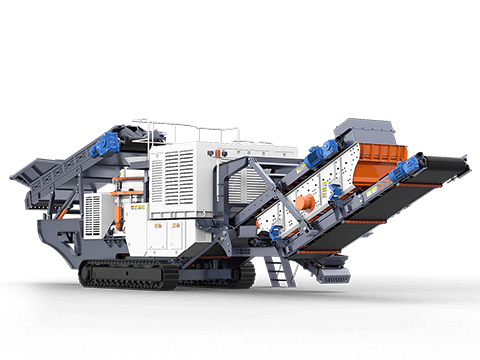

- Cambodian customers purchased our 100-ton mobile crushing production line on site

- Argentinian customers purchased our 100-ton mobile crushing production line on site

- Armenian customers purchased our 200-ton mobile crushing production line on site

- Kyrgyzstan customers purchased our grinding mill on site

- Kazakhstan customers purchased our mobile crushing station site

- Cambodian customers purchased our grinding mill on site

- Delivery site

+86 15517158123

+86 15517158123  +86 15517158123

+86 15517158123