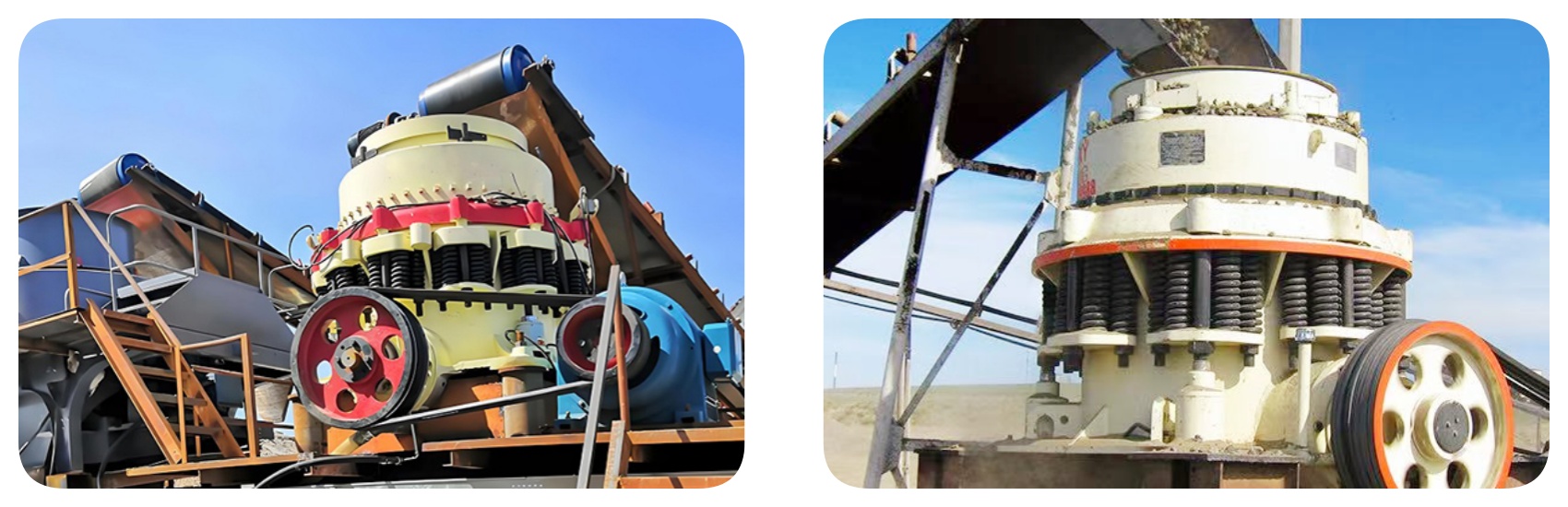

It is widely used in sand and stone field, mining, coal mining, concrete mixing station, dry mortar, power plant desulfurization, quartz sand and so on. Widely used in metallurgy, mining, chemical industry, cement, construction, refractory materials and ceramics and other industrial sectors for crushing and fine crushing medium hard ore and rock.

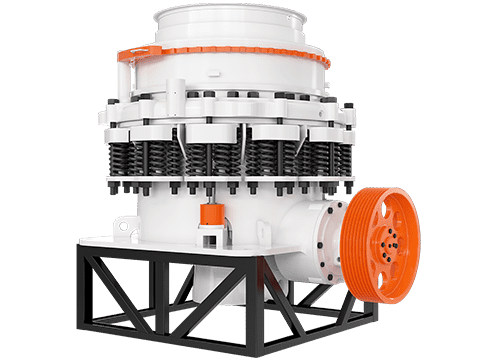

CS Spring Cone Crusher

CS Spring Cone Crusher is suitable for crushing ore and rock above medium hardness. It has a reliable structure, high production efficiency, easy adjustment, economic use, etc. The spring safety system plays an overload protection role, which can make super hard foreign matter (such as iron block, etc.) pass through the crushing chamber without damaging the machine. It adopts two sealing forms of dry oil or water to isolate the stone powder from the lubricating oil and ensure the machine operates reliably. The crushing chamber type is determined by the particle size of the finished material; the standard type is used for medium crushing operation, and the medium and short head type is used for fine crushing operation.

The CS series high-efficiency spring cone crusher, used in the black, non-ferrous metal processing process, can effectively reduce the ore into the grinding particle size to achieve more broken, less grinding. This not only improves the mill production capacity but also saves electricity and steel, greatly improving the economic benefits of the mine.

1. High efficiency crushing

High Crushing Ratio: Spring Cone Crusher adopts the principle of laminar crushing, which can realize high efficient crushing of materials, large crushing ratio and high production efficiency.

Uniform granularity: By adjusting the size of discharge opening, the granularity of the discharged material can be precisely controlled to ensure the uniformity of the product granularity to meet different production requirements.

2. Reasonable structure design

Sturdy and durable: the equipment adopts high-strength materials and optimized design, the structure is sturdy, able to withstand high-intensity workload and prolong the service life.

Convenient maintenance: the modularized design makes the maintenance and replacement of wearing parts more convenient and quick, reduces the downtime and improves the production efficiency.

3. Stable and reliable operation

Spring insurance device: the equipment is equipped with spring insurance device, when encountering unbreakable foreign objects, the spring will automatically compress to protect the equipment from damage and ensure safe operation.

Hydraulic adjustment and cavity clearing: some models are equipped with hydraulic adjustment and cavity clearing system, which can quickly adjust the size of the discharge opening and clean the crushing cavity to improve operational flexibility.

4. Wide range of applications

Multi-field application: The spring cone crusher is applicable to many industries such as mining, metallurgy, construction, chemical industry, etc. It is able to deal with various hardness materials, such as iron ore, copper ore, limestone, granite and so on.

Strong adaptability: the equipment can be adapted to different working environments and production needs, with strong versatility and adaptability.

5. Energy saving and environmental protection

Low energy consumption: the equipment adopts advanced crushing technology and optimized structure design, which can effectively reduce energy consumption and save production costs.

Environmental protection design: low noise and low dust during the operation of the equipment, which meets the requirements of environmental protection and reduces the pollution of the environment.

6. Good economy

High cost performance: Spring cone crusher has high cost performance while ensuring high performance, which can bring good economic benefits for users.

Long-term benefits: the high efficiency and durability of the equipment makes the long-term use of low cost, and can bring users sustained economic benefits.

High crushing efficiency: grate plate design, rigid hard extrusion crushing, making the fine crushing efficiency greatly improved.

Environmental and energy saving: high speed and fast operation , save electricity and reduce consumption.

Wear-resistant parts durable: more durable with wear-resistant parts material.

Low maintenance cost: compared with traditional pulverizer, energy saving is better, stable operation, maintenance cost is lower.

When the crusher works, the motor, through the elastic coupling, the drive shaft, and a pair of bevel gears, drives the eccentric shaft sleeve to rotate. The rotary pendulum movement drives the crushing cone in the eccentric sleeve, so the crushing and rolling walls are sometimes close and sometimes far away. The crushing chamber's ore is constantly squeezed, impacted, and broken.

Model | Dia. mm (feet) | Cavity | Feed Opening | Outlet Setting (mm) | Shaft Speed (r/min) | Power (kw) | Capacity (t/h) | Weight (t) | Dimension (mm) | |

Closing Side (mm) | Open Side (mm) | |||||||||

CSB75 | 900 (3') | Fine | 83 | 102 | 9-22 | 580 | 75(100) | 45-91 | 12.2 | 2821×1880×2164 |

Coarse | 159 | 175 | 13-38 | 59-163 | ||||||

CSB160 | 1295 (4 1/4') | Fine | 109 | 137 | 13-31 | 485 | 185(250) | 109-181 | 23.8 | 2800×2342×2668 |

Medium | 188 | 210 | 16-31 | 132-253 | ||||||

Coarse | 216 | 241 | 19-51 | 172-349 | ||||||

CSB240 | 1650 (5 1/2') | Fine | 188 | 209 | 16-38 | 485 | 240(320) | 181-327 | 55 | 3911×2870×3771 |

Medium | 213 | 241 | 22-51 | 258-417 | ||||||

Coarse | 241 | 268 | 25-64 | 299-635 | ||||||

Model | Dia. mm (feet) | Cavity | Feed Opening | Outlet Setting (mm) | Shaft Speed (r/min) | Power (kw) | Capacity (t/hour) | Weight (t) | Dimension (mm) | |

Closing Side (mm) | Open Side (mm) | |||||||||

CSD75 | 914 (3') | Fine | 13 | 41 | 3-13 | 580 | 75(100) | 27-90 | 12.2 | 2821×1880×2410 |

Coarse | 33 | 60 | 3-16 | 27-100 | ||||||

CSD160 | 1295 (4 1/4') | Fine | 29 | 64 | 3-16 | 485 | 160(220) | 36-163 | 23.8 | 2800×2342×2668 |

Medium | 54 | 89 | 6-16 | 82-163 | ||||||

Coarse | 70 | 105 | 10-25 | 109-227 | ||||||

CSD240 | 1676 (5 1/2') | Fine | 35 | 70 | 5-13 | 485 | 240(320) | 90-209 | 55 | 3917×2870×3771 |

Medium | 54 | 89 | 6-19 | 136-281 | ||||||

Coarse | 98 | 133 | 10-25 | 190-336 | ||||||

*The output will vary according to different materials, feed particle size and other factors

Save Time! Get A Detailed Quotation Quickly.