Mining, building materials, infrastructure construction and other industries

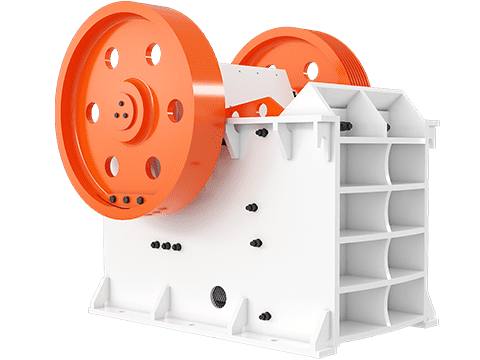

Stone Crusher

Jaw crusher is a common coarse crushing equipment, mainly used for crushing ores and rocks with higher hardness. Its working principle is to squeeze and crush materials through the periodic movement

of the movable jaw and the fixed jaw. The jaw crusher has a simple structure and is easy to maintain. It is widely used in mining, building materials, metallurgy and other fields.

It has the characteristics of high strength, high reliability, good durability, strong crushing force, large crushing particle size and high output. It is often used for primary crushing of various stone and ore

crushing production lines.

1. High crushing ratio, well-distributed final product size.

2. Discharge opening of the jaw crusher is adjustable reliably within a wide range through the stuffing of shim, thus it can meet various requirements of customers.

3. Lubrication system of it is safe and reliable, which boasts an easy and convenient maintenance.

4. Simple structure, reliable performance, low maintenance cost.

5. Little dust and low noise.

High crushing efficiency: grate plate design, rigid hard extrusion crushing, making the fine crushing efficiency greatly improved.

Environmental and energy saving: high speed and fast operation , save electricity and reduce consumption.

Wear-resistant parts durable: more durable with wear-resistant parts material.

Low maintenance cost: compared with traditional pulverizer, energy saving is better, stable operation, maintenance cost is lower.

The main parts include fixed jaw plate, movable jaw plate, eccentric shaft, connecting rod and adjusting device. The fixed jaw plate is fixed, and the movable jaw plate is driven by the eccentric shaft and connecting rod to do reciprocating motion. The material enters the crushing chamber from the top and is located between the two jaw plates. The motor drives the eccentric shaft and drives the movable jaw plate to reciprocate, and when it is close to the fixed jaw plate, it squeezes the material to make it crushed. The crushed material is discharged from the bottom by gravity. The distance between the movable jaw plate and the fixed jaw plate can be changed through the adjusting device to control the granularity of the discharged material.

Model | Feed opening (mm) | Max. Feeding Size (mm) | Adjustable Discharge opening (mm) | Capacity (t/h) | Motor Power (kW) | Overall Dimensions (mm) | Weight (t) |

PE250×400 | 250X400 | 200 | 20-60 | 5-20 | 15(20) | 1150×1275×1240 | 2.8 |

PE250x1000 | 250X1000 | 210 | 15-50 | 15-50 | 30(40) | 2790x2670x1380 | 6.5 |

PE400×600 | 400X600 | 350 | 40-100 | 15-60 | 30(40) | 1700×1732×1653 | 6.5 |

PE500×750 | 500X750 | 425 | 50-100 | 50-100 | 55(75) | 2035×1921×2000 | 10.3 |

PE600×900 | 600X900 | 500 | 65-160 | 60-130 | 75(100) | 2290×2206×2370 | 16 |

PE750×1060 | 750X1060 | 630 | 80-140 | 110-250 | 110(150) | 2620×2302×3110 | 27 |

PE900×1200 | 900X1200 | 750 | 100-200 | 160-380 | 130(175) | 3789×2826×3025 | 46.5 |

PE1000×1200 | 1000X1200 | 850 | 200-300 | 315-550 | 130(175) | 3889×2826×3025 | 56 |

PE1200×1500 | 1200X1500 | 1000 | 150-350 | 400-800 | 200(270) | 4930X3148X3560 | 88 |

*The output will vary according to different materials, feed particle size and other factors

Save Time! Get A Detailed Quotation Quickly.