Mining and stone processing, highway and railroad aggregate production, industrial solid waste disposal construction waste resource utilization and other fields.

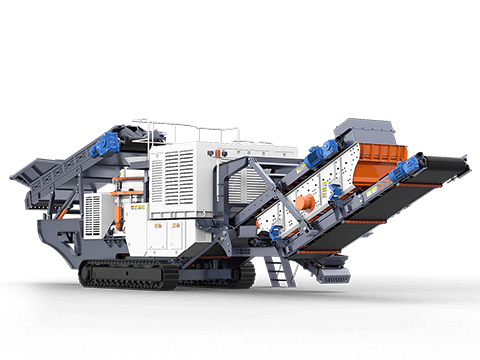

Cone Crawler Crushing Station

Crawler mobile cone crusher integrates high-efficiency crushing and intelligent operation, equipped with fully hydraulic crawler chassis, adapting to 1:6 slopes and muddy terrains, with a single machine capacity of 100-500t/h, adjustable finished product size (6-64mm), and low energy consumption of granite crushing as low as 1.4kW-h/ton (25% energy saving). Intelligent center real-time monitoring of spindle pressure, power load and other parameters, automatic adjustment of the discharge port and warning of failure, equipped with 5G remote control and multi-layer hydraulic overload protection. Pulse dust removal (dust <20mg/m³) + acoustic enclosure design (noise ≤ 78dB) to meet environmental requirements, -30℃ to 45℃ all-weather operation, module quick-disassembly structure to support 30-minute turnaround and deployment, suitable for medium-hard rock crushing, construction aggregate processing and mining two-stage crushing, the comprehensive operating costs reduced by 18%.

Five core advantages of crawler cone crusher

1: All-terrain mobility

The hydraulic crawler chassis supports 1:6 slope climbing and muddy road walking, with a turnaround speed of 1.5km/h, completing deployment in 45 minutes, adapting to complex terrain such as mines and rivers.

2: High-efficiency crushing capacity

Laminar crushing principle realizes high cubic rate (≥90%), processing capacity of 100-800t/h (granite working condition), maximum feed size of 300mm, stepless adjustable discharge size of 6-64mm.

3: Intelligent and precise control

Real-time monitoring of 12 parameters such as spindle pressure, power load, etc., automatic adjustment of discharge opening and feeding speed, 5G remote diagnosis of faults, downtime rate reduced by 60%.

4:Military grade durability

High manganese steel cone/cone liner life ≥ 10,000 hours, IP67 protection for key bearings, -30℃ low-temperature anti-freezing and 50℃ high-temperature heat dissipation design to adapt to extreme environments.

5: Modularized fast maintenance design

Hydraulic quick-disassembly structure supports 30-minute replacement of core components and 48-hour direct delivery of spare parts from 50+ service centers around the world, which saves 40% of annual maintenance cost.

High crushing efficiency: grate plate design, rigid hard extrusion crushing, making the fine crushing efficiency greatly improved.

Environmental and energy saving: high speed and fast operation , save electricity and reduce consumption.

Wear-resistant parts durable: more durable with wear-resistant parts material.

Low maintenance cost: compared with traditional pulverizer, energy saving is better, stable operation, maintenance cost is lower.

Crawler type mobile cone crusher realizes motorized deployment by fully hydraulic crawler chassis, the material enters the cone crushing chamber after pre-screening, the dynamic cone high-frequency rotary oscillation and the fixed cone form the extruding layer crushing, the discharge opening is adjusted hydraulically and infinitely from 6-64mm, and the capacity is up to 100-500t/h. The intelligent system monitors the spindle pressure and power load in real time, and matches the rotational speed and feeding capacity automatically, the crawler chassis supports 30° climbing and 1.2km/h precise positioning. The crawler chassis supports 30°climbing and 1.2km/h precise positioning, completing the transfer in 45 minutes. The -30℃ extreme cold anti-freezing design ensures the efficient crushing of medium and high hardness materials such as mines and river gravels, and the ton energy consumption is as low as 1.4kW-h, which improves the crushing efficiency by 30%.

model | Equipment configuration | Adjustable discharge port | yield | External dimension |

SL15L | ZSW3896+LF150 | 40-100 | 100-200 | 13050 x 2950 x 3100 |

SL25L | ZSW4211+LF250 | 50-120 | 200-400 | 12750 x 3000 x 3700 |

SL35L | ZSW4213+LF350 | 50-200 | 300-500 | 14360 x 3000 x 3800 |

SE69L | ZSW3896+PE69 | 60-125 | 100-180 | 12500 x 2950 x 3000 |

SC96L | ZSW3896+SC96 | 60-175 | 120-455 | 13500 x 3400 x 2800 |

SC106L | ZSW4211+SC106 | 70-200 | 155-580 | 14400 x 3600 x 3000 |

*The output will vary according to different materials, feed particle size and other factors

Save Time! Get A Detailed Quotation Quickly.