European jaw crusher crushers are widely used in the mining, quarrying, and cement industry. It has deep symmetrical crushing chamber and optimized nip angle maximizing size reduction and production capacity.

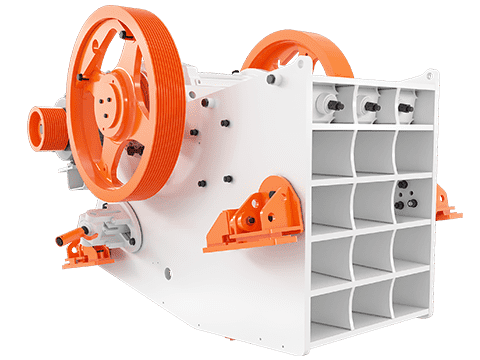

European Jaw Crusher

Jaw crusher is a common coarse crushing equipment, mainly used for crushing ores and rocks with high hardness. Its working principle is to squeeze and crush materials through the periodic movement of movable jaw and fixed jaw. With simple structure and easy maintenance, it is widely used in mining, building materials, metallurgy and other fields.

It is characterized by high strength, reliability, durability and strong crushing force. It is characterized by large crushing size and high output. It is often used as primary crusher in various stone and ore crushing production lines.

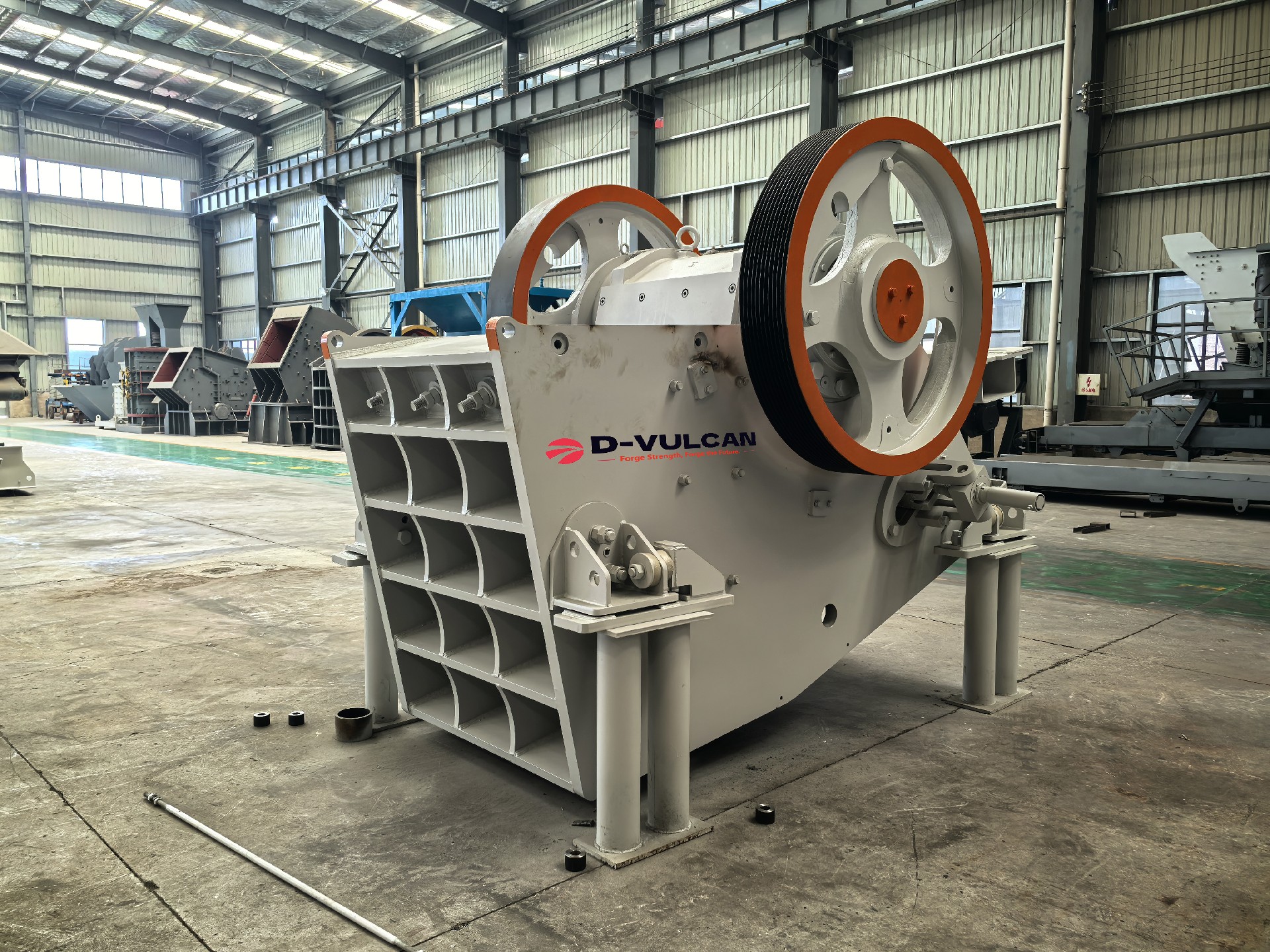

1. Moving Jaw Guard Design: A heavy-duty guard plate is installed above the moving jaw to prevent strong impact from materials and effectively protect the moving jaw body and its internal bearings from damage.

2. Integral Bearing Seat: The integral cast steel bearing seat ensures a seamless fit with the frame, eliminating unnecessary radial loads on the bearing during tightening, unlike modular bearing seats, ensuring smoother bearing

operation.

3. Convenient and Fast Particle Size Adjustment: The JC series jaw crushers utilize mechanical or hydraulic discharge adjustment mechanisms. The dual wedge adjustment method is simpler, safer, and faster than shim adjustment, reducing downtime.

4. Integrated Motor Mounting: The integrated motor mount and crusher frame not only save space and reduce V-belt length, but also extends the life of the V-belt due to the synchronized movement of the frame, mot mount, and motor, and the adjustable motor mount allows for adjustable V-belt tension.

5. Vibration-Isolating Mounting: The crusher is secured with a dedicated rubber damper, effectively absorbing vibration peaks while allowing vertical and longitudinal movement of the crusher, thereby reducing impact on the

foundation.

High crushing efficiency: grate plate design, rigid hard extrusion crushing, making the fine crushing efficiency greatly improved.

Environmental and energy saving: high speed and fast operation , save electricity and reduce consumption.

Wear-resistant parts durable: more durable with wear-resistant parts material.

Low maintenance cost: compared with traditional pulverizer, energy saving is better, stable operation, maintenance cost is lower.

The working mode of the European version jaw crusher is the bending extrusion type. Its working principle is: the motor drives the belt and pulley to make the movable jaw move up and down through the eccentric shaft. When the movable jaw rises, the included angle between the elbow plate and the movable jaw becomes larger, so as to push the movable jaw plate close to the fixed jaw plate. At the same time, the materials are crushed or split to achieve the purpose of crushing; When the movable jaw descends, the included angle between the elbow plate and the movable jaw becomes smaller, and the movable jaw plate leaves the fixed jaw plate under the action of the pull rod and spring. At this time, the crushed materials are discharged from the lower opening of the crushing chamber. With the continuous rotation of the motor, the crusher jaw makes periodic movement to crush and discharge materials, so as to realize mass production.

model | Feed port size(mm) | yield(t/h) | power(kw) | Special for fixed line |

SC80 | 800X510 | 65-380 | 75 | |

SC100 | 1000X760 | 150-545 | 110 | |

SC110 | 1100X850 | 190-625 | 160 | |

SC125 | 1250X950 | 290-845 | 160 | |

SC140 | 1400X1070 | 385-945 | 200 | |

SC160 | 1600X1100 | 520-1275 | 250 | |

SC96 | 930X580 | 120-455 | 90 | Mobile broken dedicated |

SC106 | 1060X700 | 155-580 | 110 | |

SC116 | 1150X800 | 170-600 | 132 | |

SC120 | 1200X870 | 303-529 | 160 |

*The output will vary according to different materials, feed particle size and other factors

Save Time! Get A Detailed Quotation Quickly.