Mining and stone processing, highway and railroad aggregate production, industrial solid waste disposal construction waste resource utilization and other fields

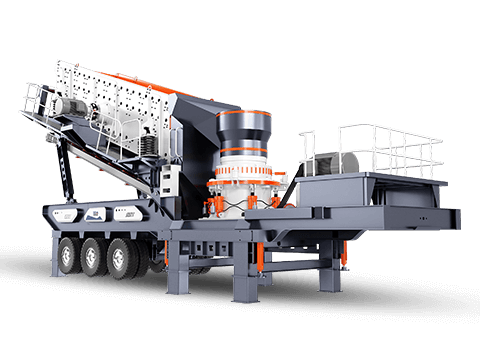

Mobile Cone Crusher Plant

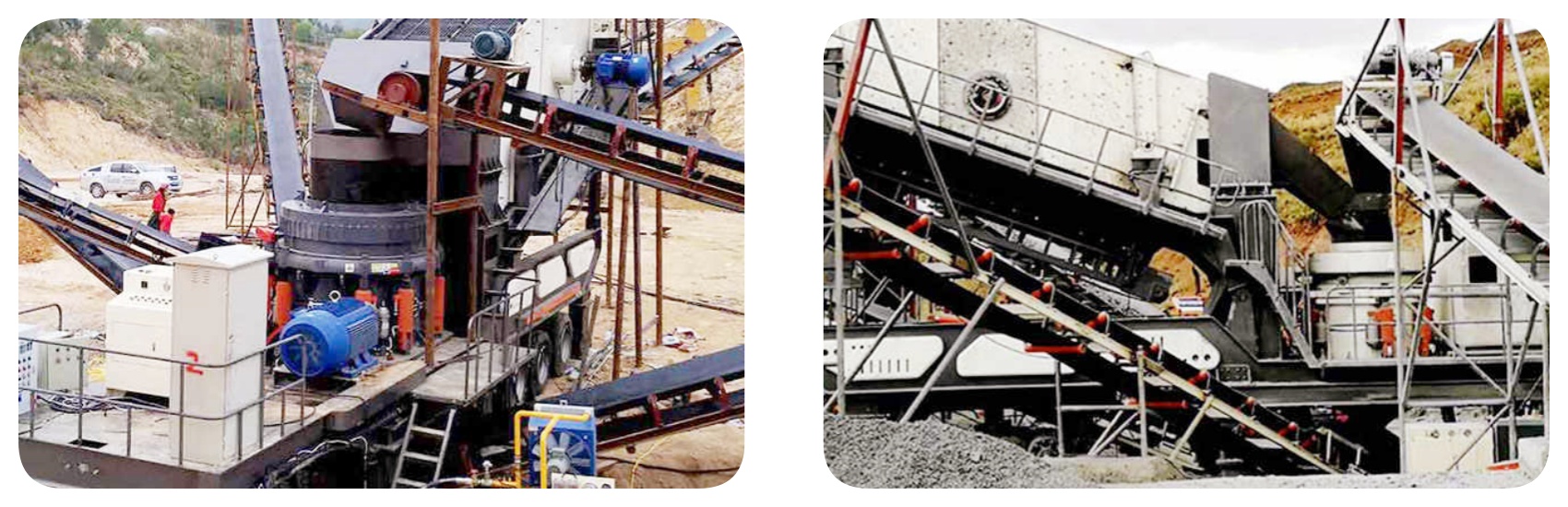

The tire-type mobile cone crushing plant adopts fully hydraulic drive chassis, equipped with four-wheel independent steering system and hydraulic outrigger stabilizer, which can realize 10-minute switching between parking and crushing modes without external traction, and the self-propelled moving speed is up to 20km/h, which is adaptable to construction sites, quarries, and other flat sites for quick transfer. The core crushing module is equipped with laminated cone mainframe, hydraulically adjustable discharge opening (8-50mm infinitely adjustable) and over-iron protection device, with a maximum capacity of 850t/h (granite conditions), and a cubic rate of ≥95% of the finished aggregate. Intelligent control center monitors the spindle pressure, lubricant temperature and current load in real time, automatically matches the feeding speed and crushing power, triggers sound and light alarms and generates fault codes for abnormal conditions, and supports 5G remote diagnosis and parameter correction. The mainframe adopts combined wear-resistant liner (life expectancy ≥ 8000 hours), hydraulic quick-disassembly structure realizes liner replacement in 30 minutes, and the integrated reclaim circulation system improves crushing efficiency by 15%. It is suitable for high abrasive materials such as basalt, iron ore, etc. The -25℃ low temperature preheating and 50℃ forced cooling ensure all-weather operation, and the single machine power consumption is as low as 1.3kW-h/ton. It can be equipped with an optional iron removal module or a three-stage screening conveyor, which can satisfy the demand for sand and gravel cogeneration and aggregate refining, and the comprehensive operation and maintenance cost is reduced by 25%.

The tire mobile cone crushing plant defines efficient crushing with four innovative advantages:

1: Dual-mode power engine

Intelligent switching between diesel engine and grid power supply, running at full load without external power supply (fuel consumption 22L/h), and switching to silent and pure power mode after accessing the grid, which reduces the comprehensive energy consumption by 18%;

2: Intelligent material adaptation system

Built-in lithology identification algorithm, real-time adjustment of eccentricity (5-50mm) and spindle speed (300-950rpm) through the current feedback, automatic matching of different hardness materials such as granite, basalt, etc., and the qualification rate of finished products is increased to 97%;

3: Zero-tool fast maintenance technology

Hydraulic locking liner and snap-type feed hopper design, without special tools to achieve the core components of the 15-minute replacement, equipped with self-lubricating bearings and centralized oil injection system, annual maintenance man-hours reduced by 60%.

4: Scenario breakthrough

Exclusive development of “crushing - dry shaping” cavity type, single machine output graded aggregate (0-5mm fine sand + 5-25mm coarse aggregate), sand and gravel cogeneration costs directly reduced by 30%, suitable for commercial mixing plant site sand demand.

High crushing efficiency: grate plate design, rigid hard extrusion crushing, making the fine crushing efficiency greatly improved.

Environmental and energy saving: high speed and fast operation , save electricity and reduce consumption.

Wear-resistant parts durable: more durable with wear-resistant parts material.

Low maintenance cost: compared with traditional pulverizer, energy saving is better, stable operation, maintenance cost is lower.

Mobile tire cone crushing plant workflow: the material through the hydraulic folding hopper (capacity 8m³) into the vibrating feeder (pre-screening 0-40mm), the impurities by the electromagnetic separator (suction ≥ 12,000 gauss) intercept, qualified material into the cone crushing chamber. The moving cone rotates at high speed and the fixed cone forms laminar pressure crushing, and the discharge opening (5-50mm) is adjusted hydraulically and infinitely, and the finished products are transported to the screening system through the main conveyor belt at the bottom (with a width of 1.4m and a speed of 0-4m/s), and are classified into 0-5mm, 5-20mm and 20-50mm aggregates through the three-decker vibrating screen (with the aperture of screen mesh of 3-60mm can be exchanged), and the over-limit materials are automatically crushed by the return material belt. Intelligent central control monitors the crushing pressure, screening efficiency and conveying load in real time, and dynamically optimizes the feeding rate and screen inclination angle (0-15°), with the hard rock handling capacity stabilized at 300-600t/h, and the closed-loop control error of the whole process ≤3%, and the finished product rate of the single-machine sand and gravel co-production reaches 95%.

Standard model | Supporting equipment | Supporting equipment | External dimension (mm) | ||

model | Feed size (mm) | Processing capacity (T / h) | |||

S-CS75 | 3YZK1848 | CS75 | ≤160 | 59-163 | 12600×2800×4400 |

S-CS110 | 3YZK1860 | CS110 | ≤178 | 100-200 | 13800×3000×4400 |

S-CS160 | 3YZK2160 | CS160 | ≤188 | 132-253 | 13800×3000×4400 |

S-CS220 | 3YZK2160 | CS220 | ≤230 | 215-330 | 14500×3000×4500 |

S-HQ300 | 3YZK1848 | SHQ300 | ≤160 | 65-168 | 12600×2800×4400 |

S-HQ400 | 3YZK1860 | SHQ400 | ≤230 | 105-205 | 13800×3000×4400 |

S-HQ500 | 3YZK2160 | SHQ500 | ≤240 | 180-290 | 14500x3000x4600 |

S-H420 | 3YZK1848 | SH420 | ≤240 | 85-170 | 12600×2900×4400 |

S-H430 | 3YZK1860 | SH430 | ≤360 | 120-345 | 13800×3000×4500 |

S-H440 | 3YZK2160 | SH450 | ≤450 | 255-605 | 14800×3200×4600 |

S-HP100 | 3YZK1860 | SHP100 | ≤140 | 75-140 | 13800×2900×4300 |

S-HP200 | 3YZK2160 | SHP200 | ≤185 | 145-250 | 14200×3000×4500 |

S-HP300 | 3YZK2160 | SHP300 | ≤230 | 220-440 | 16500×3200×4600 |

S-PF1214 | 3YZK1860 | PF1214 | ≤300 | 100-200 | 14500×2900×4500 |

S-PF1315 | 3YZK2160 | PF1315 | ≤350 | 130-280 | 15200×3000×4500 |

S-PF1320 | 3YZK2460 | PF1320 | ≤500 | 180-400 | 15200×3000×4500 |

S-S1860 | 3YZK1860 | ≤400 | 65-586 | 10500×2700×4200 | |

S-S2160 | 3YZK2160 | ≤400 | 81-720 | 10500×3000×4500 | |

S-S2460 | 3YZK2460 | ≤400 | 100-810 | 10500×3200×4500 | |

*The output will vary according to different materials, feed particle size and other factors

Save Time! Get A Detailed Quotation Quickly.