It is widely used in medium and fine crushing operations in mining, metallurgy, building materials, chemical industry and other industries.

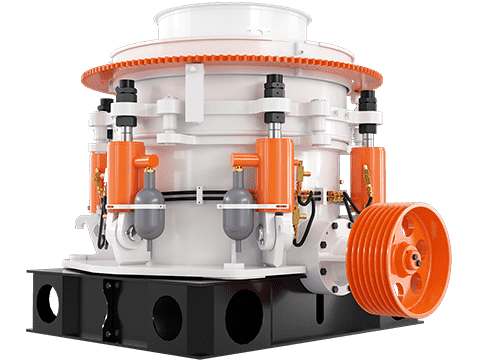

HP Multi-cylinder Cone Crusher

HPT Multi-cylinder hydraulic cone crusher is a piece of typical crushing equipment for medium and fine crushing hard materials, which is mainly used in the two-stage crushing and three-stage crushing link in metal mining and construction sand processing. Multi-cylinder hydraulic cone crusher because hydraulic devices realize its safety, adjustment, and locking, so it also has the advantages of convenient adjustment of ore discharge, small overload coefficient through non-crushing objects, easy to take out the non-crushing objects blocked in the crushing chamber.

1. Fixed spindle: The equipment has a strong carrying capacity, a more compact structure, a small size, and high efficiency.

2. It was designed by adopting the principle of intergranular lamination. Utilizing the mutual extrusion of materials, the crushing efficiency and the proportion of fine materials are significantly improved, the needle and flake materials are greatly reduced, and the steel consumption of wearing parts is reduced.

3. Advanced bearing design, using tin bronze bushing sliding bearing design. Compared with rolling bearings, the equipment can maintain ultra-high load capacity in high-dust and high-impact environments and has low production costs.

4. A temperature sensor is installed at the oil return position of the horizontal axis to accurately detect the oil temperature and ensure stable operation of the equipment; the transmission system uses spiral bevel gears to ensure reliable and stable transmission.

5. The liner fixing method is improved While the cone wall is thickened. This eliminates the need for glue filling, making replacement very convenient and fast and reducing maintenance costs.

6. Integrated hydraulic lubrication and unique thin oil lubrication system design greatly extend the service life of the equipment. High-performance, non-contact labyrinth seals are more conducive to ensuring the cleanliness of lubricating oil.

7. The oil circuit of the safety cylinder adopts large-diameter oil pipes and large-capacity accumulators, which have better buffering performance, faster response, and safer equipment.

8. The standard floating installation base makes the installation simple, labor-saving, and time-saving, with reduced foundation requirements and low user investment.

High crushing efficiency: grate plate design, rigid hard extrusion crushing, making the fine crushing efficiency greatly improved.

Environmental and energy saving: high speed and fast operation , save electricity and reduce consumption.

Wear-resistant parts durable: more durable with wear-resistant parts material.

Low maintenance cost: compared with traditional pulverizer, energy saving is better, stable operation, maintenance cost is lower.

The crushing principle of Hydraulic Cone Crusher is finished between fixed cone plate and movable cone plate. The cone crusher ’s motor drives the horizontal axis of the cocrusherthrough triangle belt and pulley, the horizontal axis drive the eccentric shaft bush to rotate through gear transmission. The eccentric shaft drives the main shaft to make the movable cone plate swing at a regulated track from time to time, the materials are crushed due to constant pressed and crooked in the crushing cavity. The finished products are discharged from the discharging open

Type | Cavity (coarse/fine) | Close Side feed opening(mm) | Min CSS (mm) | Capacity (tPh) | Power KW(HP) |

HPT300 | C1 Extra Coarse | 230 | 25 | 220-440 | 250(350) |

C2 Coarse | 210 | 20 | 190-380 | ||

M Medium | 150 | 16 | 175-320 | ||

F1 Fine | 105 | 13 | 110-260 | ||

F2 Extra Fine | 80 | 10 | 100-240 | ||

HPT500 | C1 Extra Coarse | 330 | 38 | 425-790 | 400(500) |

C2 Coarse | 290 | 30 | 380-700 | ||

M Medium | 210 | 22 | 330-605 | ||

F1 Fine | 130 | 16 | 270-535 | ||

F2 Extra Fine | 95 | 13 | 200-430 | ||

HPT800 | C1 Extra Coarse | 350 | 38 | 545-1200 | 630(850) |

C2 Coarse | 300 | 32 | 495-1050 | ||

M Medium | 265 | 25 | 470-950 | ||

F1 Fine | 220 | 17 | 385-730 | ||

F2 Extra Fine | 150 | 14 | 310-600 | ||

F3 Extra Fine | 90 | 10 | 260-550 |

*The output will vary according to different materials, feed particle size and other factors

Save Time! Get A Detailed Quotation Quickly.