Widely used in mining, metallurgy, building materials, water conservancy, industry, renewable resources processing and other industries in the medium crushing, fine crushing, ultra-fine crushing operations.

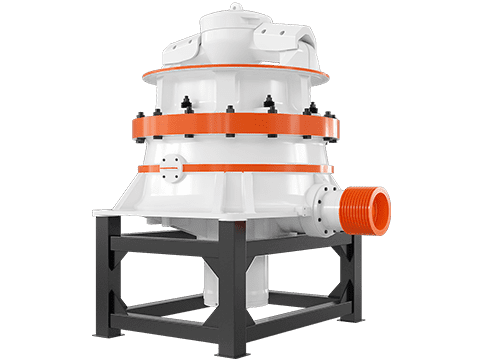

CS Single Cylinder Cone Crusher

CS series single-cylinder hydraulic cone crusher adopts innovative single-cylinder hydraulic control system, which integrates hydraulic adjustment, overload protection and cavity clearing functions, and is suitable for medium and fine crushing operations. Equipped with heavy-duty spindle structure (600r/min swing times) and high-performance crushing cavity, the machine can handle feed size ≤560mm, realizing high capacity of 45-1200t/h, and the discharge size can be adjusted accurately from 6-41mm by hydraulic device. The standard intelligent TC1000 automatic control system monitors the operation status in real time, and the maintenance efficiency is increased by 40% with the thin oil lubrication system and modularized design. Especially suitable for granite, basalt and other hard rock crushing, the power configuration covers 90-750kW, energy consumption is reduced by 25% compared with traditional models, meets CE, ISO certification standards, is a modernized stone production line of high efficiency and energy saving solutions.

Five core advantages Reshaping the new standard of single-cylinder crusher

1: High efficiency and energy saving

Laminated crushing technology reduces energy consumption by 25% and saves $20,000-40,000 annually under the same output.

600r/min high stroke rotational speed, the production capacity is increased by 40% compared with the traditional model, up to 1200t/h.

2: Intelligent automation

TC1000 intelligent control system real-time monitoring (bearing temperature ±1℃ precision/vibration value <4mm/s warning)

Hydraulic adjustment system to complete the adjustment of the discharge particle size in 3 minutes (stepless adjustment from 6-41mm)

3: Maintenance revolution

Modularized design shortens the replacement time of core components by 60% (the main frame body can be dismantled in 4 hours).

Thin oil lubrication system extends bearing life by 2.3 times and reduces annual maintenance cost by 40%.

4: Hard Rock Nemesis

Unique G-shape crushing cavity can handle materials with Mohs hardness class 8 (granite/basalt crushing ratio up to 1:6).

Hydraulic overload protection system can withstand ≤300MPa instantaneous impact load.

5: Safety and Environmental Protection

CE certification system to ensure that the pulse dust removal interface to achieve dust emissions <20mg/m³.

Fully enclosed structure makes the operation noise ≤85dB(A).

High crushing efficiency: grate plate design, rigid hard extrusion crushing, making the fine crushing efficiency greatly improved.

Environmental and energy saving: high speed and fast operation , save electricity and reduce consumption.

Wear-resistant parts durable: more durable with wear-resistant parts material.

Low maintenance cost: compared with traditional pulverizer, energy saving is better, stable operation, maintenance cost is lower.

The motor drives the horizontal shaft to rotate, and the horizontal shaft drives the eccentric sleeve to rotate through the gear. Then the eccentric sleeve drives the moving cone to swing in a circle, so as to realize the continuous extrusion and crushing of materials. By adjusting the hydraulic cylinder at the bottom of the cone, the cone can be moved up and down to conveniently adjust the size of the discharge opening and product size. At the same time, the hydraulic cylinder also has the function of anti-iron. When objects that cannot be crushed (such as iron) enter the crushing chamber, the hydraulic cylinder will automatically lower the cone to release the iron and protect the crusher. After the foreign objects are discharged, the dynamic cone automatically recovers. The equipment resumes working condition and continues crushing.

Model | Cavity | Maximum feed size(mm) | CSS min-max(mm) | Capacity(tph) | Power KW(HP) | Dimension (L×W×H) (mm) | Weight (t) |

HST100 | S1(Extra Coarse) | 240 | 22-38 | 85-170 | 90(125) | 1535×1275×2710 | 9.6 |

S2(Medium Coarse) | 200 | 19-32 | 70-130 | ||||

HST160 | S1(Extra Coarse) | 360 | 25-54 | 120-345 | 132(175) | 2045×1635×3040 | 15.5 |

S2(Medium Coarse) | 300 | 22-48 | 105-305 | ||||

S3(Coarse) | 235 | 19-48 | 90-275 | ||||

HST250 | S1(Extra Coarse) | 450 | 35-54 | 255-605 | 220(300) | 2675×2550×3940 | 28 |

S2(Medium Coarse) | 400 | 29-51 | 215-515 | ||||

S3(Coarse) | 300 | 25-51 | 190-490 | ||||

HST315 | S1(Extra Coarse) | 560 | 41-76 | 335-1050 | 315(400) | 3110×2945×4480 | 43.5 |

S2(Medium Coarse) | 500 | 38-70 | 305-895 | ||||

Model | Cavity | Maximum feed size(mm) | CSS min-max(mm) | Capacity(tph) | Power KW(HP) | Dimension (L×W×H) (mm) | Weight (t) |

HST100 | H1(Fine) | 135 | 10-32 | 45-130 | 90(125) | 1540×1280×2300 | 7.5 |

H2(Medium Fine) | 65 | 8-19 | 35-80 | ||||

H3(Extra Fine) | 38 | 4-16 | 27-60 | ||||

HST160 | H1(Fine) | 185 | 13-38 | 66-210 | 132(175) | 2000×1550×2600 | 10 |

H2(Medium Fine) | 90 | 10-32 | 65-165 | ||||

H3(Extra Fine) | 50 | 6-25 | 48-105 | ||||

HST250 | H1(Fine) | 215 | 16-44 | 110-395 | 220(300) | 2315×1830×2940 | 19.5 |

H2(Medium Fine) | 110 | 13-38 | 115-340 | ||||

H3(Extra Fine) | 70 | 8-32 | 90-255 | ||||

HST315 | H1(Fine) | 275 | 16-51 | 170-665 | 315(400) | 2740×2200×3590 | 28.5 |

H2(Medium Fine) | 135 | 16-38 | 190-505 | ||||

H3(Extra Fine) | 65 | 13-22 | 205-320 | ||||

HST560 | H1(Fine) | 300 | 22-70 | 448-1331 | 560(750) | 3300×2600×4463 | 51 |

H2(Medium Fine) | 155 | 19-70 | 400-1098 | ||||

H3(Extra Fine) | 80 | 10-44 | 280-669 | ||||

HST750 | H1(Fine) | 270 | 25-70 | 480-2500 | 630(850) | 3800×3100×5305 | 80 |

H2(Medium Fine) | 195 | 22-70 | 552-1115 | ||||

H3(Extra Fine) | 85 | 10-51 | 364-790 |

*The output will vary according to different materials, feed particle size and other factors

Save Time! Get A Detailed Quotation Quickly.