Mining and stone processing, highway and railroad aggregate production, industrial solid waste disposal construction waste resource utilization and other fields

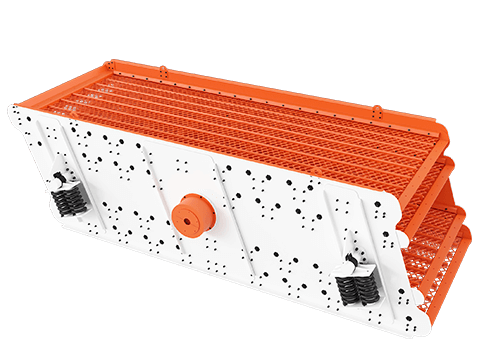

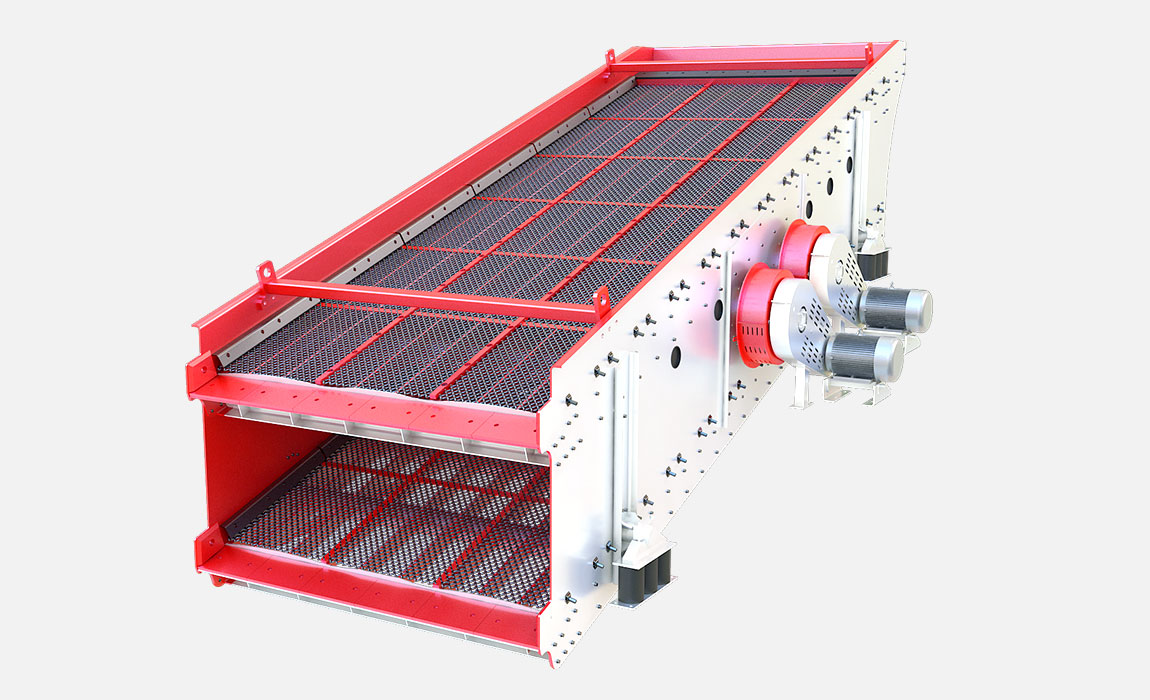

Circular vibrating screen

circular vibrating screen is mainly composed of screen box, screen mesh, exciter, damping spring device and chassis. Cylindrical eccentric shaft exciter and eccentric block are used to adjust the amplitude. The vibrator is mounted on the side plate of the screen box, driven to rotate by the motor through the triangular belt, which generates centrifugal inertia force and forces the screen box to vibrate. The side plate of the screen machine is made of high quality steel plate, and the side plate is connected with the cross beam and the base of the vibration exciter through high-strength bolts or ring groove rivets. The vibrator is mounted on the side plate of the screen box, driven to rotate by the motor through the coupling, generating centrifugal inertia force and forcing the screen to vibrate.

Product Advantage

1、Multi-layer high-efficiency screening:

2-4 layers of screen mesh (aperture 3-150mm) stepped layout, using polyurethane / manganese steel composite screen plate (life ≥ 12 months), screening efficiency ≥ 95%, capacity up to 50-1200t/h, suitable for aggregate classification and tailings dewatering multi-scenario.

2、Dual frequency excitation technology:

Dual vibration motors (power 1.5-30kW) support high-frequency/low-frequency mode switching (speed 750-1500rpm), amplitude 2-8mm stepless adjustment, accurately match the wet and dry material screening needs, and reduce the over-powder rate by 20%.

3、Intelligent shock absorption system:

Rubber-spring composite damping seat + dynamic balance calibration, the vibration conductivity of the equipment <5%, the foundation bearing requirements reduced by 40%, the noise ≤ 75dB, to meet the urban environmental standards.

4、Quick-change screen design:

Modularized screen frame (single layer replacement ≤ 15 minutes) and hydraulic locking device, support tool-free disassembly and installation, maintenance efficiency increased by 50%, annual downtime reduced by 30%.

High crushing efficiency: grate plate design, rigid hard extrusion crushing, making the fine crushing efficiency greatly improved.

Environmental and energy saving: high speed and fast operation , save electricity and reduce consumption.

Wear-resistant parts durable: more durable with wear-resistant parts material.

Low maintenance cost: compared with traditional pulverizer, energy saving is better, stable operation, maintenance cost is lower.

Working Principle

Through the single-drive and double-drive motor (power 15-90kW) synchronous reverse rotation to generate directional excitation force, drive the screen box with a frequency of 25-50Hz for three-dimensional elliptical motion, the material in the screen surface (amplitude 2-8mm adjustable) on the stratified jump forward, fine particles through the sieve holes (aperture 3-150mm) down, coarse materials along the screen surface discharge, to achieve multi-stage particle size sorting. Intelligent control system monitors the vibration parameters and load status in real time, dynamically adjusts the angle and speed of the motor bias block (750-1500rpm), and switches between high-frequency (fines screening) or low-frequency (wet sticky material anti-clogging) mode, with screening efficiency ≥95%. Elastic rubber spring damping system isolates more than 80% of the vibration transmission, with anti-clogging hole elastic ball (≥98% clear clogging rate) and fast tensioning screen structure, suitable for -30 ℃ to 120 ℃ working conditions. Capacity of 50-1200t/h, can be customized with the number of screen decks (2-4 decks) and screen plate material (polyurethane/manganese steel), to meet the sand and gravel, metallurgical tailings and recycled aggregates dry and wet method of accurate grading.

Model | Sieve specification (mm) | layer | Mesh size (mm) | Max feeding size (mm) | Processing capacity (t/h) | Moto power (kw) | Vibrating Frequency (r/min) | Double amplitude (mm) |

2YK1237 | 1200X3700 | 2 | 3-50 | 200 | 30-100 | 5.5 | 970 | 5-9 |

3YK1237 | 1200X3700 | 3 | 3-50 | 200 | 30-100 | 7.5 | ||

2YK1548 | 4800X1500 | 2 | 3-100 | 400 | 30-275 | 15 | ||

3YK1548 | 4800X1500 | 3 | 3-100 | 30-275 | 15 | |||

2YK1848 | 4800X1800 | 2 | 3-100 | 56-330 | 18.5 | |||

3YK1848 | 4800X1800 | 3 | 3-100 | 56-330 | 18.5 | |||

4YK1848 | 4800X1800 | 4 | 3-80 | 56-330 | 22 | |||

2YK1860 | 6000X1800 | 2 | 3-100 | 65-586 | 18.5 | |||

3YK1860 | 6000X1800 | 3 | 3-100 | 65-586 | 22 | |||

4YK1860 | 6000X1800 | 4 | 3-100 | 65-586 | 30 | 980 | ||

2YK2160 | 6000X2100 | 2 | 3-100 | 81-720 | 22 | 980 | ||

3YK2160 | 6000X2100 | 3 | 3-100 | 81-720 | 30 | 970 | ||

4YK2160 | 6000X2100 | 4 | 3-100 | 81-720 | 37 | 980 | ||

2YK2460 | 6000X2400 | 2 | 3-150 | 100-810 | 22 | 970 | ||

3YK2460 | 6000X2400 | 3 | 3-150 | 100-810 | 30 | 980 | ||

4YK2460 | 6000X2400 | 4 | 3-150 | 150-850 | 37 | 980 | ||

2YK2470 | 7000X2400 | 2 | 3-100 | 180-900 | 30 | 980 | ||

3YK2470 | 7000X2400 | 3 | 3-100 | 180-900 | 37 | 980 | ||

4YK2470 | 7000X2400 | 4 | 3-100 | 180-900 | 45 | 980 | ||

2YK2480 | 8000X2400 | 2 | 3-150 | 190-940 | 30 | 980 | ||

3YK2480 | 8000X2400 | 3 | 3-150 | 190-940 | 37 | 980 | ||

4YK2480 | 8000X2400 | 4 | 3-150 | 190-940 | 45 | 980 | ||

2YK3070 | 7000X2400 | 2 | 3-100 | 220-1000 | 37 | 980 | ||

3YK3070 | 7000X2400 | 3 | 3-150 | 220-1000 | 45 | 980 | ||

4YK3070 | 7000X2400 | 4 | 3-150 | 220-1000 | 55 | 980 |

*The output will vary according to different materials, feed particle size and other factors

Save Time! Get A Detailed Quotation Quickly.