mining,metallic minerals,Quarries, construction industry

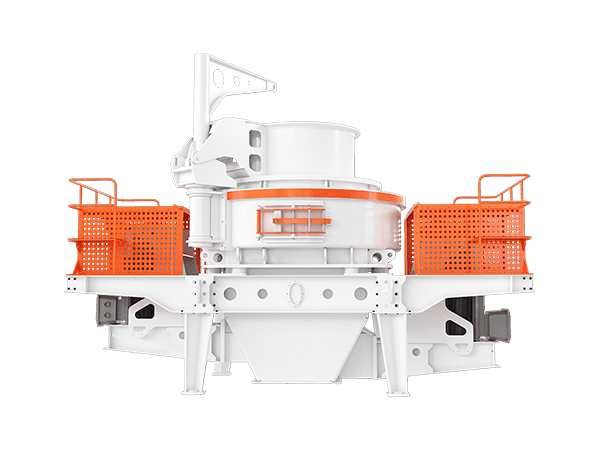

VSI high efficiency sand making machine

The VSI high-efficiency sand making machine is a high-performance sand making machine developed based on the actual sand making conditions in China and utilizing the latest technological advances. It perfectly combines crushing technology with mechanical engineering. Its unique rotor structure, wear-resistant materials, and hydraulic technology enable it to provide high-quality sand and gravel aggregate for highways, high-speed railways, high-rise buildings, municipal projects, hydropower dam construction, and concrete mixing plants. It is an ideal choice for artificial sand making and stone shaping. Its exceptional cost-effectiveness and sophisticated engineering ensure that the VSI high-efficiency sand making machine holds a leading position in the domestic sand making equipment industry.

1. Low cost and minimal wear

The VSI high-efficiency sand making machine has a simple and rational structure, low wear, and low operating costs.

2. Powerful functions and excellent sand production results

The VSI high-efficiency sand making machine features both fine and coarse crushing, a high crushing rate, and is environmentally friendly and energy-efficient.

3. Wide range of materials

The VSI high-efficiency sand making machine is suitable for crushing medium-hard and extra-hard materials. It is minimally affected by the moisture content of the material and can crush stones with a moisture content of approximately 8%.

4. Energy-saving and environmentally friendly, with minimal dust pollution

The VSI high-efficiency sand making machine has an operating noise level of less than 75 decibels, producing minimal dust pollution. The product is cubic, has a high bulk density, and is extremely low in iron pollution.

High crushing efficiency: grate plate design, rigid hard extrusion crushing, making the fine crushing efficiency greatly improved.

Environmental and energy saving: high speed and fast operation , save electricity and reduce consumption.

Wear-resistant parts durable: more durable with wear-resistant parts material.

Low maintenance cost: compared with traditional pulverizer, energy saving is better, stable operation, maintenance cost is lower.

Material falls into the VSI high-efficiency sand making machine's feed hopper, enters the high-speed rotating impeller through the center feed hole, and is rapidly accelerated within the impeller, reaching accelerations up to several times the acceleration of gravity. It is then ejected from the impeller at high speed, first colliding with the material that has rebounded and is now in free fall. This material then strikes the material lining (rock on rock) or the impact block (rock on iron), where it is rebounded upward and impacts the top of the vortex chamber. There, it changes direction, deflecting downward and colliding with material ejected from the impeller flow channel, forming a continuous material curtain. In this way, a piece of material undergoes two or more collisions, friction, and grinding within the vortex crushing chamber. The crushed material is discharged through the lower discharge port.

Standard model | Supporting equipment | Supporting equipment | External dimension (mm) | ||

model | Feed size (mm) | Processing capacity (T / h) | |||

S-V7611 | 3YZK1548 | VSI7611 | 35 | 120-180 | 12500 x 2600 x 4300 |

S-V8518 | 3YZK1848 | VSI8518 | 40 | 200-260 | 14200 x 3000 x 4500 |

S-V9526 | 3YZK1860 | VSI9526 | 45 | 300-380 | 14500 x 3000 x 4500 |

S-V1140 | 3YZK2160 | 5X1140 | 50 | 450-520 | 15500 x 3100 x 4500 |

S-5V7615 | 3YZK1548 | 5X7615 | 35 | 150-280 | 12500 x 2600 x 4300 |

S-5V8522 | 3YZK1848 | 5X8522 | 40 | 240-380 | 14200 x 3000 x 4500 |

S-5V9532 | 3YZK1860 | 5X9532 | 45 | 350-540 | 14500 x 3000 x 4500 |

S-5V1145 | 3YZK2160 | 5X1145 | 50 | 500-640 | 15500 x 3100 x 4500 |

*The output will vary according to different materials, feed particle size and other factors

Save Time! Get A Detailed Quotation Quickly.