Natural sand and gravel aggregate, mechanism sand (crushed granite, limestone), industrial slag, construction waste recycled aggregate, special working conditions materials

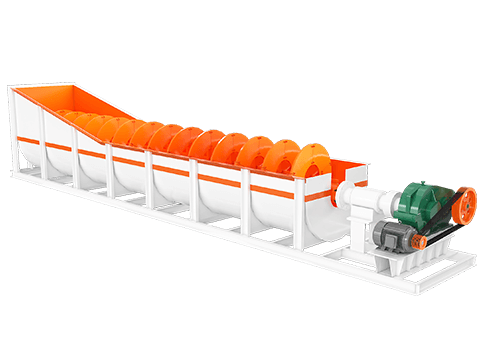

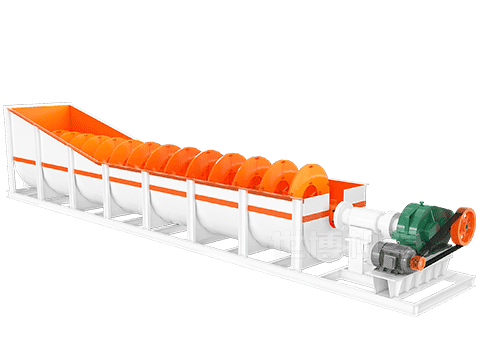

Spiral Sand Washing Machine

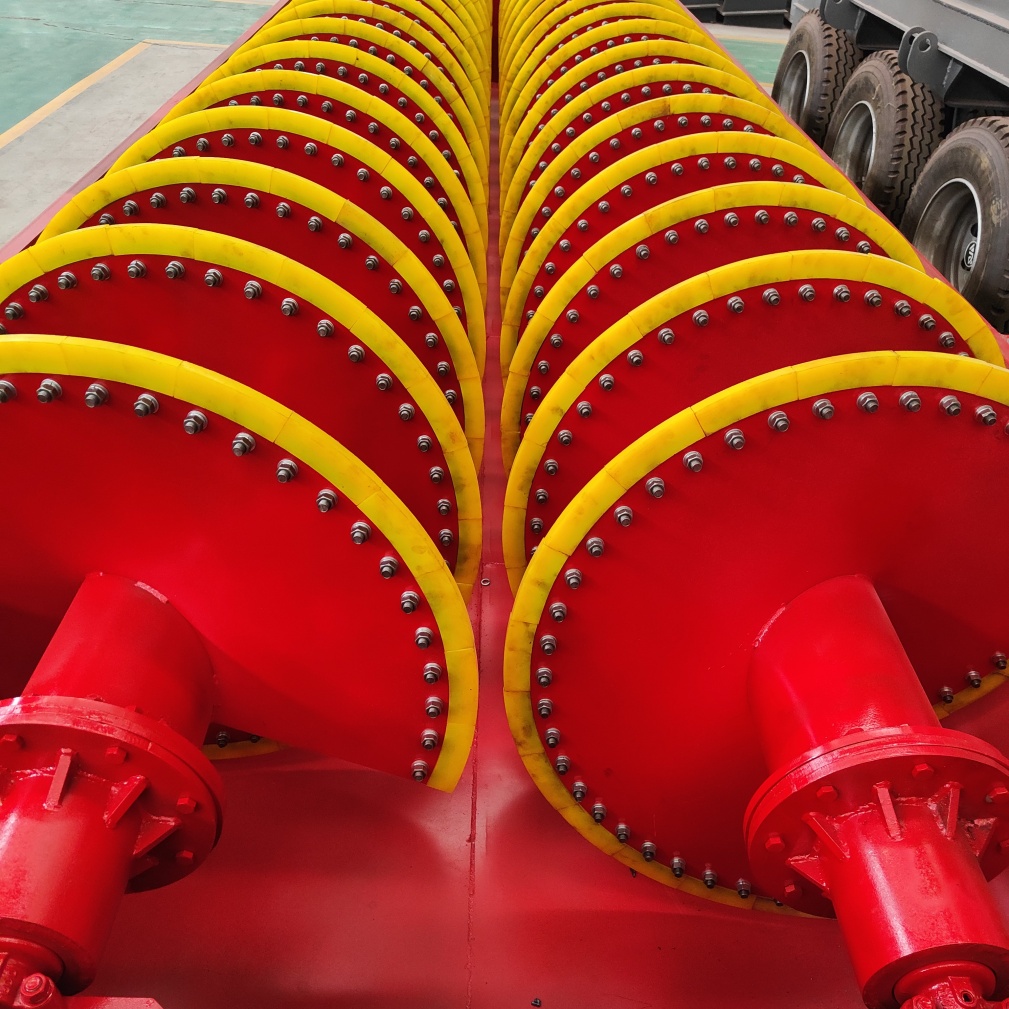

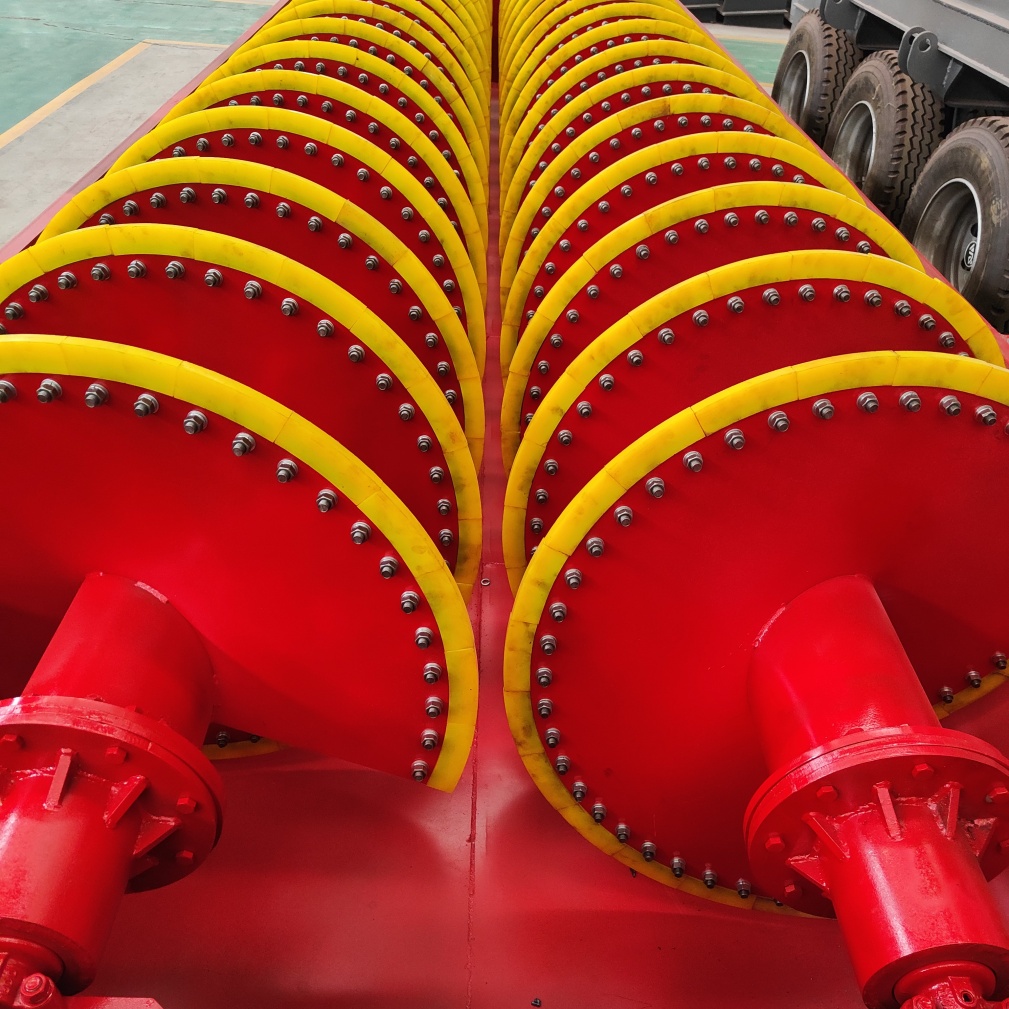

Screw sand washing machine is divided into double screw and single screw. It can wash and separate the sand and debris in the soil, and its novel sealing structure, adjustable overflow weir plate and reliable transmission device ensure the effect of washing and dewatering. It is widely used in highway, hydropower, construction and other industries for washing, grading, removing impurities and washing of fine and coarse materials and other operations, which is especially suitable for gravel for building and road construction.

Product Advantage

1: Professionally designed deflector plate and adjustable long overflow weir plate, together with optimized screw rotating speed, make the washing and grading of materials more precise.

2: Optimized design of discharge chute can ensure the limit of removing moisture from materials.

3: Simple machine structure, stable operation, can be applied to various working environments.

4: Few wearing parts, low failure rate and long service life.

High crushing efficiency: grate plate design, rigid hard extrusion crushing, making the fine crushing efficiency greatly improved.

Environmental and energy saving: high speed and fast operation , save electricity and reduce consumption.

Wear-resistant parts durable: more durable with wear-resistant parts material.

Low maintenance cost: compared with traditional pulverizer, energy saving is better, stable operation, maintenance cost is lower.

Working Principle

Spiral sand washer work, the material from the upper part of the machine into the high-speed rotating impeller, under the action of high-speed centrifugal force, the other part of the umbrella flow around the impeller, high-speed impact on the material and crushing, the material after the impact of the vortex between the chassis to form a number of times each other impact, friction and crushing, from the lower part of the direct discharge, the formation of the closed circuit many times, controlled by the screening equipment to achieve the desired size of the finished product.

| model | Screw diameter (mm) | Tank length (mm) | Feed size (mm) | Screw speed (R / min) | Production capacity (T / h) | Power (kw) | Water consumption (T / h) | Overall dimension (mm) |

| XL515 | 515 | 7615 | ≤10 | 38 | 5-15 | 5.5 | 6-60 | 8100X2345X1450 |

| XL765 | 765 | 7620 | ≤10 | 26 | 20-60 | 11 | 9-63 | 8545X2650X1870 |

| XL920 | 920 | 7585 | ≤10 | 100 | 40-110 | 11 | 10-80 | 8500X2100X3600 |

| 2XL920 | 920 | 7585 | ≤10 | 200 | 80-220 | 2X11 | 20-160 | 8420X3760X3960 |

| XL1120 | 1120 | 9750 | ≤10 | 175 | 50-130 | 18.5 | 20-150 | 1078X3980X4170 |

| 2XL1120 | 1120 | 9750 | ≤10 | 350 | 100-260 | 2X18.5 | 40-300 | 1097X5250X4720 |

*The output will vary according to different materials, feed particle size and other factors

Save Time! Get A Detailed Quotation Quickly.