Metallurgy, building materials, chemicals, laboratories, mining

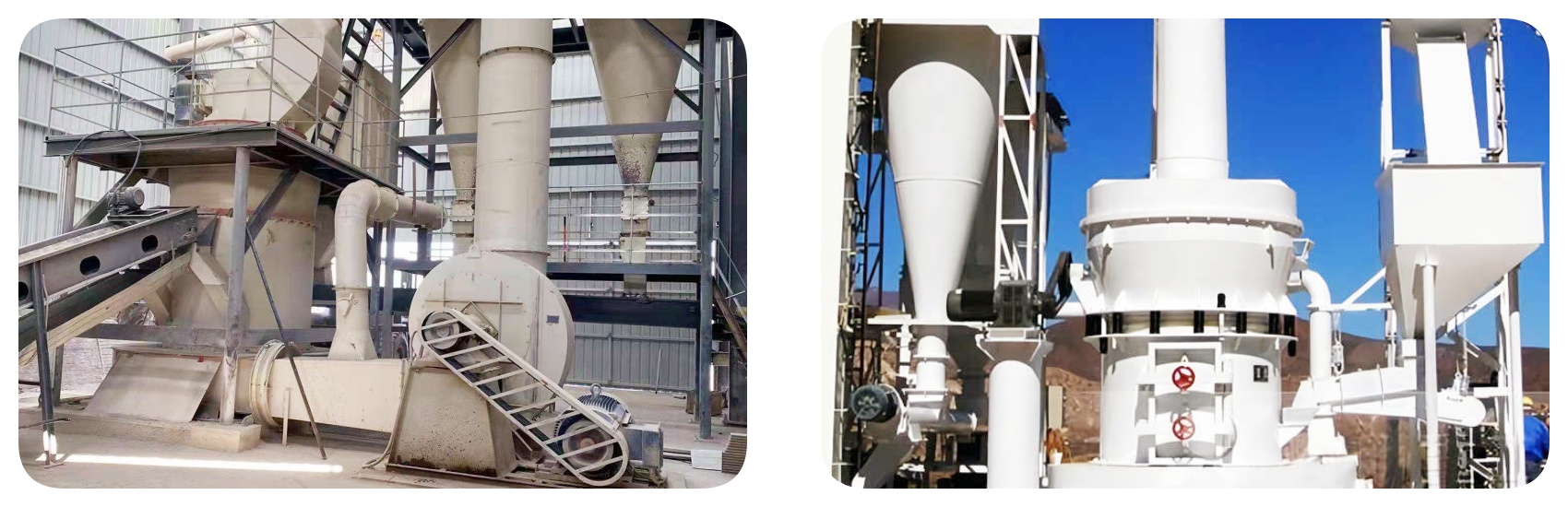

Raymond vertical mill is used to grind barite, calcite, feldspar, talc, marble, limestone, cream and slag below 7 moth hardness and 280 in mining, construction materials, chemical engineering and metallurgy for power generation and processing. The final product size of Raymond vertical mill can be adjusted in the range of 100-325 mesh.

1) Reduced powder consumption and increased production capacity.

2) Stable and reliable performance.

3) Fineness: 30-425 mesh (adjustable)

4) 1000 hours of operation without lubrication

High crushing efficiency: grate plate design, rigid hard extrusion crushing, making the fine crushing efficiency greatly improved.

Environmental and energy saving: high speed and fast operation , save electricity and reduce consumption.

Wear-resistant parts durable: more durable with wear-resistant parts material.

Low maintenance cost: compared with traditional pulverizer, energy saving is better, stable operation, maintenance cost is lower.

The material first enters the crusher to reduce it to a smaller size. It then travels to the storage chamber via an elevator. A vibrating feeder evenly and gradually delivers the material into the Raymond vertical mill chamber. After grinding, the powder is blown toward the cyclone by a blower. The material is then transferred via a duct to the storage chamber and discharged as the final product. The entire process of the Raymond vertical mill operates in a negative pressure environment. First, air from the blower, along with the powder, enters the cyclone collector above the storage chamber through a duct, and then returns to the blower via a return duct. Furthermore, the air can be recycled. A powder lock device is located below the cyclone in the Raymond vertical mill, isolating the positive external pressure from the negative pressure inside the cyclone. This ensures high productivity. Furthermore, residual air and dust below the main unit are transferred via a duct to a dust collector, where they are cleaned. The clean air is then discharged, thus protecting the environment.

Model | Piece of roller | Size of the roller (mm) | Size of the ring (mm) | Feed size(mm) | Fineness of powder (mm) | Capacity (t/h) | Motor power (kW) | Weight (without motor)(t) |

YGM65 | 3 | Φ210×150 | Φ650×150 | ≤15 | 0.033-0.613 | 0.4-1.8 | 15 | 3.6 |

YGM75 | 3 | Φ260×150 | Φ780×150 | ≤15 | 0.033-0.613 | 1-3 | 18.5 | 4.8 |

YGM85 | 3 | Φ270×150 | Φ830×150 | ≤20 | 0.033-0.613 | 1.2-4 | 22 | 8 |

YGM95 | 4 | Φ310×170 | Φ950×170 | ≤25 | 0.033-0.613 | 2.1-5.6 | 37 | 14 |

YGM130 | 5 | Φ410×210 | Φ1280×210 | ≤30 | 0.033-0.613 | 2.5-9.5 | 75 | 24 |

*The output will vary according to different materials, feed particle size and other factors

Save Time! Get A Detailed Quotation Quickly.