Applicable to mining, cement, coal, metallurgy, building materials, highway, fuel and other departments.

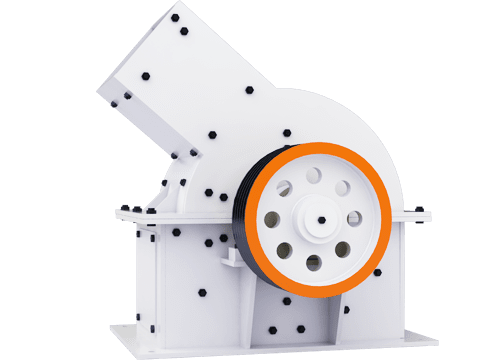

PC Hammer Crusher

PC Hammer Crusher is suitable for crushing medium hardness and brittle materials in mining, cement, coal, metallurgy, building materials, highway, coal gasification and other industries. The machine has simple structure, large crushing ratio, high production efficiency, and can be used for dry or wet crushing. The grate slit of the machine can be adjusted according to the user's requirements to obtain different final particle sizes to meet the different needs of different users.

1.convenient maintenance

2.wear resistant and impact resistant

3.compact structure,lees easy-wearing parts

4.sealed structure,less pollution and ash leakage of machine

5. The granularity can be adjusted according to the requirement

High crushing efficiency: grate plate design, rigid hard extrusion crushing, making the fine crushing efficiency greatly improved.

Environmental and energy saving: high speed and fast operation , save electricity and reduce consumption.

Wear-resistant parts durable: more durable with wear-resistant parts material.

Low maintenance cost: compared with traditional pulverizer, energy saving is better, stable operation, maintenance cost is lower.

PC series hammer crusher takes high energy-efficiency crushing as the core, adopts heavy rotor (rotational speed 750-1200rpm) and high chrome alloy hammer head (life expectancy ≥4000 hours), realizes high efficient crushing of medium-hard materials such as limestone, gangue and so on (compressive strength ≤150MPa), with the feed size ≤100mm, capacity of 20-100t/h, and the finished product size of 5-40mm adjustable steplessly, and the needle flake content <10%. Needle flake content <10%. Intelligent monitoring system real-time tracking bearing temperature and vibration data, overload 0.5 seconds shutdown protection, failure rate reduced by 35%. The modular hammerhead group supports quick maintenance, adapting to open-pit mine and construction solid waste recycling scenarios, with power consumption as low as 0.6kW-h per ton, optional pre-screening device or inverter drive module, reducing the comprehensive operating costs by 25%, meeting the needs of large-scale aggregate production and resource recycling.

model | Feed size (mm) | Discharge particle size (mm) | Production capacity (T / h) | Power (kw) | Weight (T) | External dimension (mm) |

PCФ400×300 | ≤200 | ≤25 | 5-10 | 11 | 0.8 | 900 × 670 × 860 |

PCФ600×400 | ≤250 | ≤30 | 10-22 | 22 | 2.26 | 1200 × 1050 × 1200 |

PCФ800×600 | ≤250 | ≤35 | 18-40 | 55 | 4.8 | 1310 × 1180 × 1310 |

PCФ1000×800 | ≤350 | ≤35 | 25-50 | 75 | 5.9 | 1600 × 1390 × 1575 |

PCФ1000×1000 | ≤500 | ≤35 | 30-80 | 90 | 8 | 1800 × 1590 × 1775 |

*The output will vary according to different materials, feed particle size and other factors

Save Time! Get A Detailed Quotation Quickly.