Copper ore, gold ore, limestone, granite, basalt, slag, coal gangue, phosphorus ore, sulfur ore, cement clinker, high alumina bauxite, magnesia, quartzite, coal, waste bricks, concrete blocks and so on.

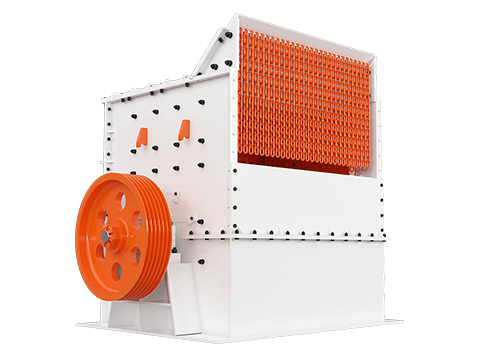

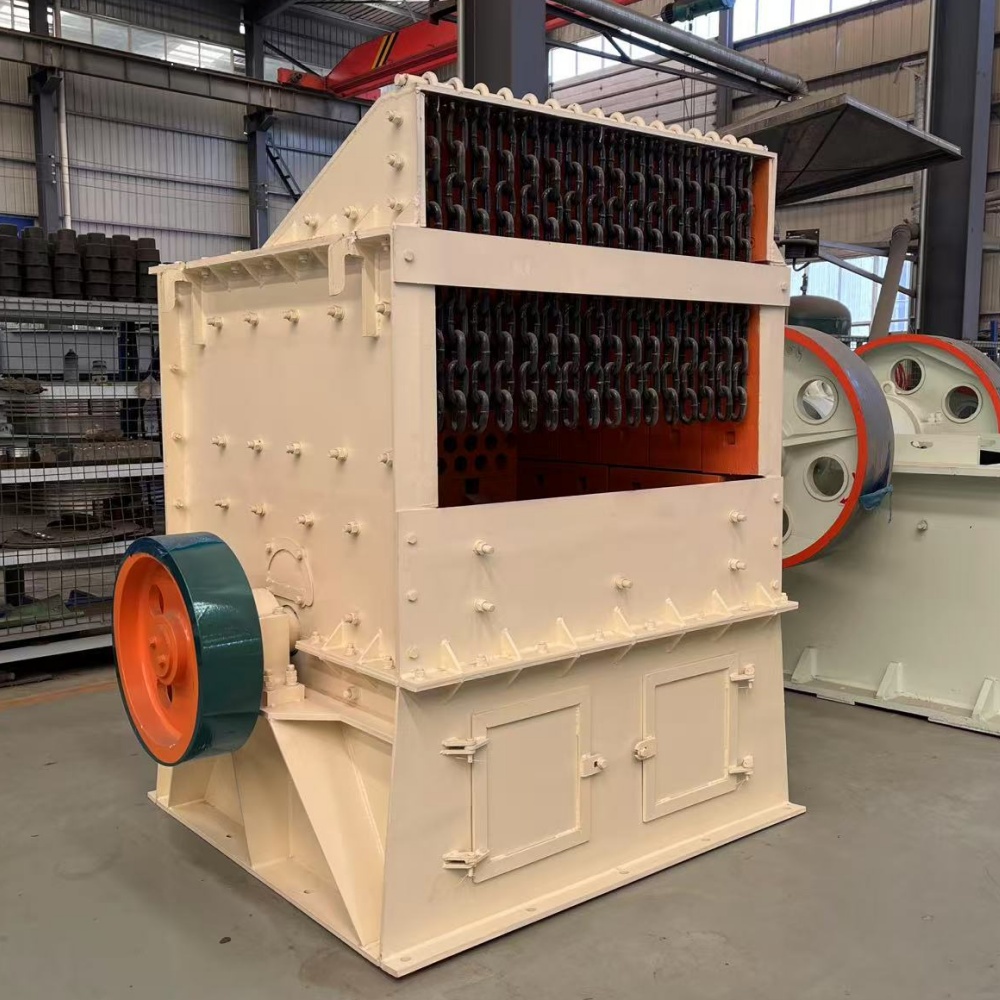

PC Box Crusher

PC Box Crusher is a kind of medium and fine crushing equipment with closed box structure, which realizes high efficient crushing through the high-speed rotor driving hammer head or plate hammer impacting materials.Its features include compact structure, convenient maintenance (box can be opened and closed), good dust control, the maximum compressive strength of crushed materials does not exceed 150kg/cm, suitable for processing coal, limestone, construction waste and other medium-hardness materials, widely used in mining, building materials and solid waste recycling and other fields, both high output and environmental protection advantages.

1. large feed size, large crushing ratio, uniform discharge, high output, lower energy consumption per unit than traditional jaw crusher;

2. environmental protection and noise reduction, closed box effectively suppresses dust spillage and reduces operational noise, in line with green production requirements;

3. modular design, the box can be opened and closed, easy to quickly replace the hammer head, screen plate and other wear parts, reduce downtime;

4. Rough and medium crushing can be completed in one step, simplifying the process flow;

5. hammer head, hammer plate and impact plate are made of high wear-resistant materials, longer service life;

6. strong adaptability, can be adjusted through the rotor speed, screen gap and other parameters, flexible control of the discharge size (5-50mm), to meet a variety of materials crushing needs;

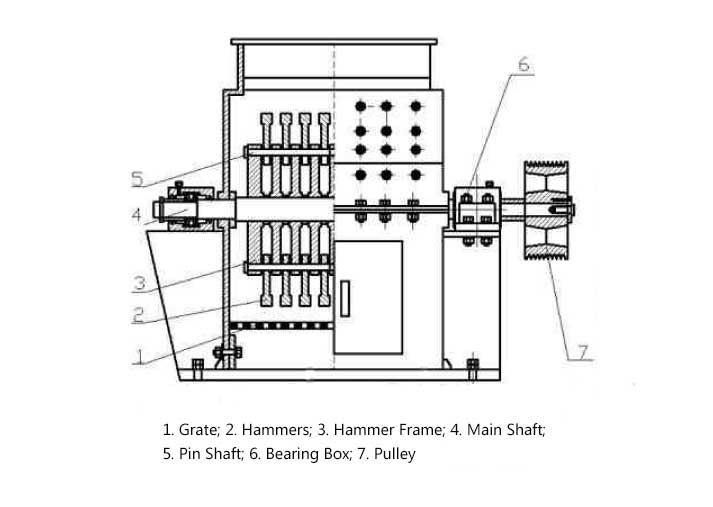

High crushing efficiency: grate plate design, rigid hard extrusion crushing, making the fine crushing efficiency greatly improved.

Environmental and energy saving: high speed and fast operation , save electricity and reduce consumption.

Wear-resistant parts durable: more durable with wear-resistant parts material.

Low maintenance cost: compared with traditional pulverizer, energy saving is better, stable operation, maintenance cost is lower.

After the material enters into the closed box from the top inlet, the motor-driven high-speed rotor drives the hammer head or plate hammer, exerting strong impact, extrusion and grinding on the material; the crushed particles fall down under the effect of gravity, filtered through the adjustable gap screen plate at the bottom, the material that meets the requirements of the particle size is discharged, and those that are not up to the standard are rebounded to the crushing chamber to continue to be crushed, and the cycle is until it reaches the standard. The core of the machine is to realize continuous and efficient crushing process through the kinetic energy conversion of the rotor and the particle size control of the screen plate.

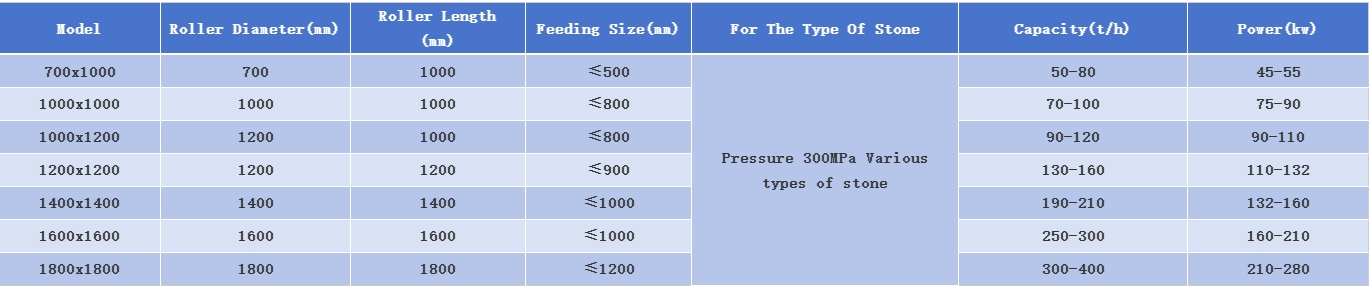

*The output will vary according to different materials, feed particle size and other factors

Save Time! Get A Detailed Quotation Quickly.