Domestic and foreign construction, ore, metallurgy industry, highway, railway, bridge, hydropower, mineral grinding and machine-made sand industry

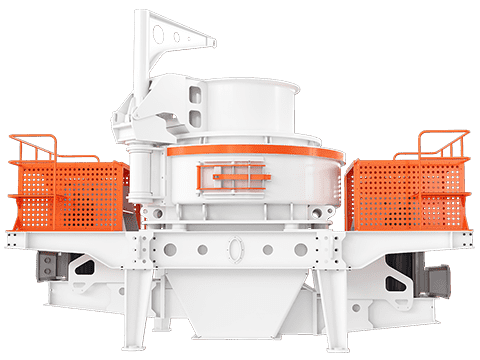

5X Sand Making Machine of Description

5X Sand Making Machine is our company's latest-generation product, with the latest technology from Germany, and it has several independent patent rights. It is a model of the perfect combination of professional crushing technology and mechanical manufacturing and a full embodiment of new technologies and new processes. It can not only provide the highest quality sand and gravel aggregate for highways, high-speed railways, high-rise buildings, municipal projects, hydropower dam construction, port terminals, concrete mixing stations, etc., but has also become the undisputed core of the machine-made sand industry and stone shaping fields. Equipment has increasingly become mainstream in metal ore crushing, quartz sand production, steel slag processing, and other fields. 5X Sand Making Machine is a new high-efficiency crushing machine recognized worldwide.

It has the following unique features and advantages.

1. After the optimized design of the deep cavity rotor, the material throughput is increased by about 30%.

2. After the partially worn peripheral guard plate, it can be turned up and down to improve material utilization and extend the service life by more than 48%. The wear-resistant block combined design only needs to replace the worn parts, which can reduce the use cost by more than 30%.

3. The core wear-resistant materials are highly wear-resistant and high-temperature materials used in important industries in the United States.

4. Use diamond-shaped impact blocks to avoid damage to the vertical plate after material impact and wear.

5. The optimal launch port and smoother curved design inside reduce the flow resistance of materials and greatly improve the material passing capacity.

6. Dual-purpose bulk material tray is easy to operate and can easily switch between two feeding methods.

7. The special sealing structure at the lower end of the spindle ensures no oil leakage without an oil seal.

8. The hydraulic cover opening device using originally imported accessories can move the upper cover conveniently and quickly, saving labor and effort when replacing and repairing internal parts of the machine body.

9. Choose motors with high protection levels. This type of motor has the characteristics of high efficiency and low noise. It must comply with International Electrotechnical Commission (IEC) standards, have Class F insulation, and have an IP54/55 protection level.

High crushing efficiency: grate plate design, rigid hard extrusion crushing, making the fine crushing efficiency greatly improved.

Environmental and energy saving: high speed and fast operation , save electricity and reduce consumption.

Wear-resistant parts durable: more durable with wear-resistant parts material.

Low maintenance cost: compared with traditional pulverizer, energy saving is better, stable operation, maintenance cost is lower.

When entering into impeller, the raw material can be crushed directly by hitting impact plate after it is accelerated and threw out. The raw material can also be divided into two parts by material-dividing plate. One falls down from all around. The other enters into impeller and is accelerated, threw out and collides with the falling material and hit, rebound with impact plate. The circulation hits repeats. As the crushing is moving forward, small particle materials will gradually form a material bed around the impact plate which can improve the crushing effect and protect the machine. The desired artificial sand comes downwards though outlet finally.

Model | VSI5X7615 | VSI5X8522 | VSI5X9532 | VSI5X1145 | |

Throughput capacity (t/h) | Center and Ring feeding | 150~280 | 240~380 | 350~540 | 500~640 |

Center feeding | 70~140 | 120~190 | 180~280 | 250~360 | |

Max. Feed Size (mm) | Soft material | <35 | <40 | <45 | <50 |

Hard material | <30 | <35 | <40 | <45 | |

Rotation speed (r/min) | 1700~1900 | 1500~1700 | 1300~1510 | 1100~1310 | |

Power of double motor (KW) | 2×75 (100) | 2×110 (150) | 2×160 (220) | 2×220 (300) | |

Overall dimension L×W×H (mm) | 4100×2330×2300 | 4140×2500×2700 | 4560×2600×2900 | 5000×2790×3320 | |

Weight (t) | 8.6 | 11.8 | 17.5 | 27.5 | |

Thin oil lubrication station | Power for double oil pump | 2×0.25(0.33) | |||

Safety | TO make sure the supply of the oil with double oil pump; stop working without oil or hydraulic pressure; temperature falls when the water cool;start the motor by heating it in winter | ||||

Power for oil box heater | 2 KW | ||||

Overall dimension L×W×H (mm) | 820×520×1270 | ||||

*The output will vary according to different materials, feed particle size and other factors

Save Time! Get A Detailed Quotation Quickly.