Natural sand and gravel aggregate, mechanism sand (crushed granite, limestone), industrial slag, construction waste recycled aggregate, special working conditions materials

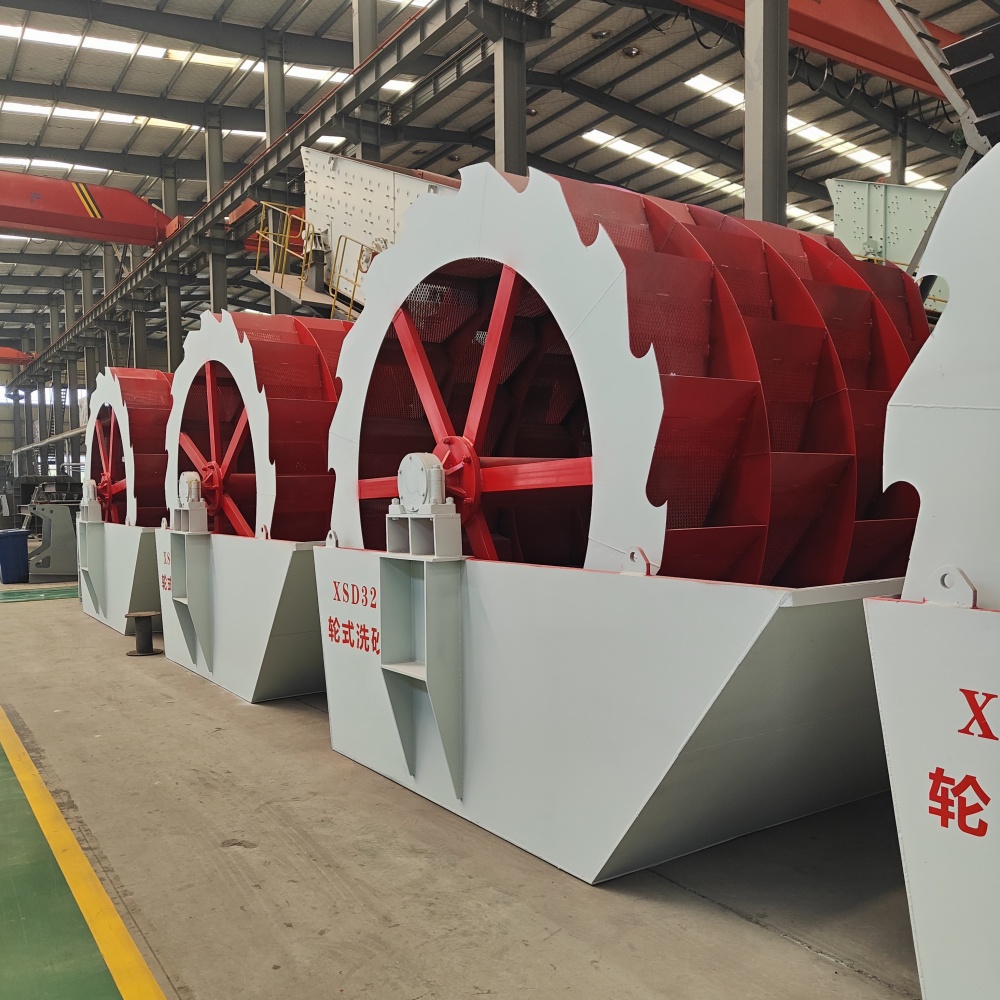

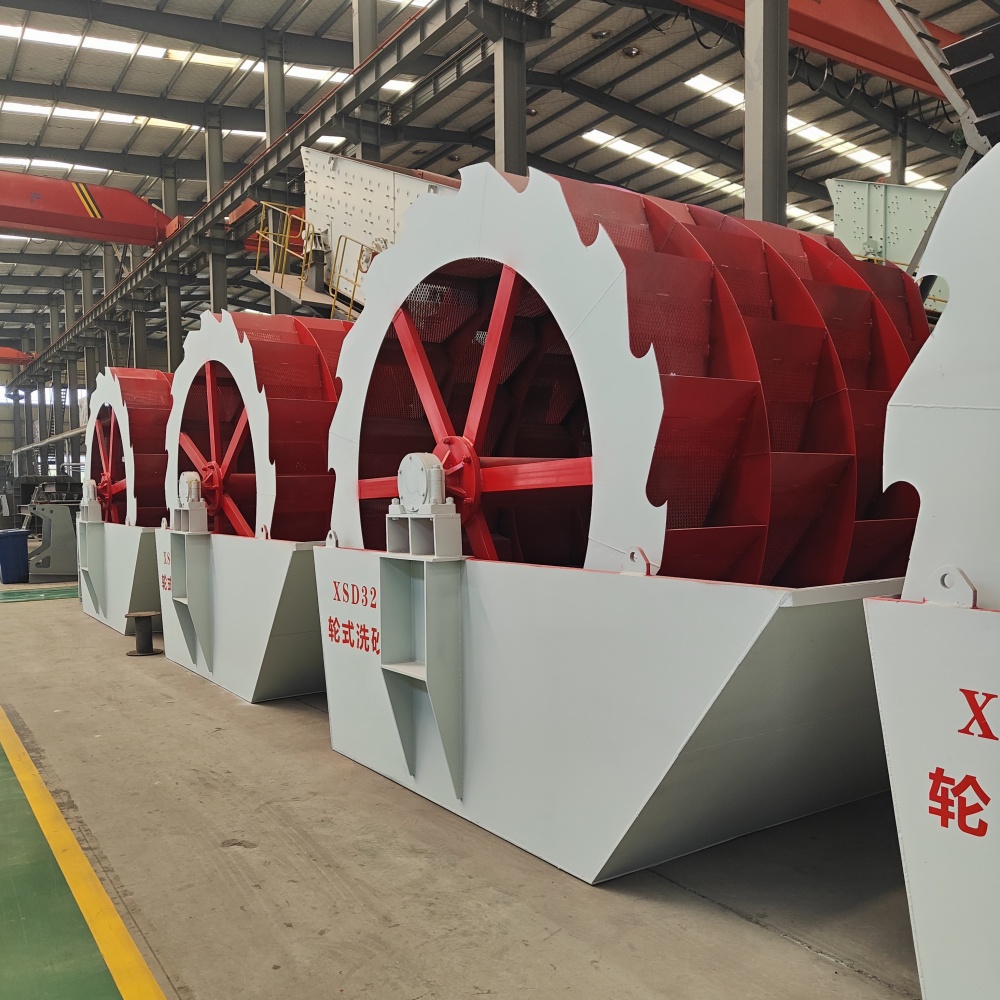

Bucket Wheel Sand Washing Machine

The sand washing machine, which adopts advanced technology, is a high-efficiency sand washing equipment designed based on the actual conditions of China's sand and gravel industry. It features high washing height, reasonable structure, high productivity and minimal sand loss during the washing process. In addition, the equipment is equipped with sand and stone isolation function, so that the failure rate is much lower than that of modern sand washing machines, which is an optimal solution for the modernization of the domestic sand washing industry. Keqiang sand washing machine is made of special wear-resistant and corrosion-resistant materials and can work in any harsh environment, which greatly extends its service life. In addition, the sand washing machine has high energy-saving capacity.

The sand washing machine is widely used in artificial sand production lines. It is widely used for processing quartz sand, river sand, yellow sand, sea sand and other types of sand. It is used to remove dirt and impurities from sand, which can achieve the standard of sand washing and sorting.

Product Advantage

1: Novel sealing structure, fully enclosed oil bath transmission device, adjustable overflow weir plate to ensure that the series of products are durable, good cleaning and dewatering effect, and stable fine-grained products.

2: The machine adopts impeller drive bearing device and water material separation design, which avoids the damage to the machine caused by premature pollution and rusting, so the failure rate is much lower than other commonly used sand washing machines.

3: Except for the screen mesh, the machine has almost no wearing parts and seldom needs maintenance, so the cost of use can be greatly reduced.

4: The cleanliness of the cleaned material is high, no pollution, and the loss of medium and fine sand and stone powder is very small.

High crushing efficiency: grate plate design, rigid hard extrusion crushing, making the fine crushing efficiency greatly improved.

Environmental and energy saving: high speed and fast operation , save electricity and reduce consumption.

Wear-resistant parts durable: more durable with wear-resistant parts material.

Low maintenance cost: compared with traditional pulverizer, energy saving is better, stable operation, maintenance cost is lower.

Working Principle

When the sand washing machine works, the motor drives the impeller to rotate slowly after decelerating through the triangle belt and deceleration gear. At the same time, it destroys the water vapor layer covering the sand grains and promotes dewatering; at the same time, it adds water to form a strong water current, which takes away the impurities and foreign materials with small specific gravity in time and discharges them from the overflow cleaning tank to complete the cleaning effect. Clean gravel is taken away by the blades, and the gravel is poured into the discharge tank from the rotating impeller to complete the cleaning of gravel.

| model | Impeller diameter (mm) | Feed size (mm) | Processing capacity (T / h) | Power (kw) | External dimension (mm) |

| XSD2610 | Ф2600 | ≤10 | 30-60 | 7.5 | 3320 × 2125 ×2670 |

| XSD2900 | Ф2900 | ≤10 | 50-90 | 15 | 3810 × 2686 × 3085 |

| XSD3016 | Ф3000 | ≤10 | 80-120 | 18.5 | 3845 × 3000 × 3080 |

| XSD3220 | Ф3000 | ≤10 | 120-200 | 22 | 4150 × 3780 × 3400 |

| XSD3620 | Ф3600 | ≤10 | 150-280 | 30 | 4600 × 3780 × 3900 |

*The output will vary according to different materials, feed particle size and other factors

Save Time! Get A Detailed Quotation Quickly.