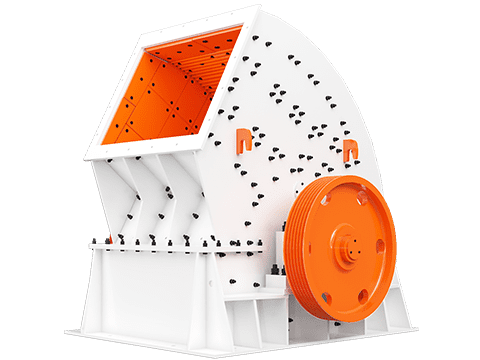

PCZ series heavy hammer crusher is also called huge stone cusher. Because of the alloy composite hammer design, it decrease 35% production cost.

Heavy hammer crusher, also known as hammer crusher, has the advantages of one-time forming, large crushing ratio, high production capacity, uniform product particle size, etc. it is suitable for fine crushing limestone, coal or other brittle materials with medium hardness in metallurgical, building materials, chemical industry, water and electricity and other industrial departments. We are a crushing equipment manufacturer specializing in R & D, design and production of heavy hammer crushers. The price of Hammer Crushers is reasonable, and the product structure is advanced With reliable performance and low energy consumption, it has formed a series of products, which are deeply loved by new and old customers.

Heavy hammer crusher uses impact to crush materials. The main working part is the rotor with hammer head, which is composed of main shaft, disc, pin shaft and hammer head. The motor drives the rotor to rotate at high speed in the crushing chamber. The materials enter the machine from the upper feeding port and are crushed by the impact, impact and grinding of the high-speed hammer. The lower part of the rotor is provided with a sieve plate. The particle size smaller than the size of the sieve hole in the crushed material is discharged through the sieve plate, and the coarse particle size larger than the size of the sieve hole is blocked on the sieve plate, which continues to be hit and ground by the hammer, and is discharged through the sieve plate.

High crushing efficiency: grate plate design, rigid hard extrusion crushing, making the fine crushing efficiency greatly improved.

Environmental and energy saving: high speed and fast operation , save electricity and reduce consumption.

Wear-resistant parts durable: more durable with wear-resistant parts material.

Low maintenance cost: compared with traditional pulverizer, energy saving is better, stable operation, maintenance cost is lower.

The heavy hammer crusher can be formed at one time without secondary crushing and shaping process, which can reduce the cost by about 40%. It has the advantages of large crushing ratio, high output, uniform particle size of finished products, low energy consumption and high environmental protection.

| model | Specifications | feed sizemm) | feed port size(mm) | throughput(t/h) | motor power(kw) | Overall dimension(mm) |

| PCZ0706 | 700x570 | 618x510 | ≤400 | 75 | 50-70 | 1950x1340x1480 |

| PCZ0808 | 800x750 | 780x610 | ≤500 | 132 | 80-100 | 2280x1790x1670 |

| PCZ0910 | 900x1000 | 1070x750 | ≤600 | 150-200 | (110kw-4)*2 | 2600x2200x2050 |

| PCZ1012 | 1000x1180 | 1255x810 | ≤200 | 250-300 | (132kw-4)*2 | 2800x2400x2300 |

| PCZ1213 | 1200x1280 | 1350x900 | ≤200 | 300-350 | (160kw-4)*2 | 2970x2625x2580 |

| PCZ1216 | 1270x1490 | 1530x920 | ≤250 | 400-500 | (200kw-4)*2 | 3070x2840x2580 |

| PCZ1220 | 1220x1950 | 2000x920 | ≤250 | 500-700 | (250kw-4)*2 | 3080x2280x2580 |

| PCZ1622 | 1580x2150 | 2290x960 | ≤300 | 600-900 | 630kw-6 | 4095x3495x2960 |

*The output will vary according to different materials, feed particle size and other factors

Save Time! Get A Detailed Quotation Quickly.