Mainly used in metallurgy, chemical industry, hydropower engineering and other industries.

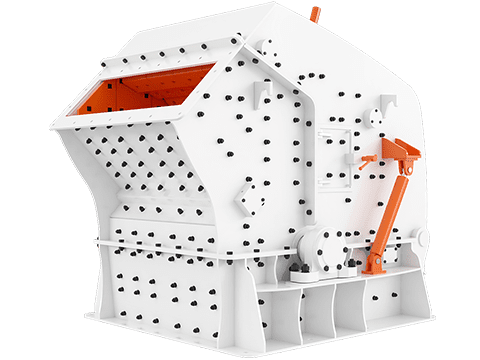

PF Impact Crusher

An impact crusher is a crushing machine that uses impact energy to crush materials. This crushing equipment can handle various materials with a particle size not exceeding 1000 mm and a compressive strength not exceeding 350 MPa. It has a large crushing ratio, high crushing efficiency, and easy maintenance. The product is cube-shaped and is an ideal processing equipment for aggregates used in highway and hydropower construction. Impact crushers are widely used in highway construction, water conservancy projects, and construction gravel processing due to their stable performance.

1.Big crushing ratio, high crushing efficiency, cubic shape production.

2.The gap between plate hammer and impact hammer can be adjusted, and the discharging size can be controlled effectively.

3.The high chrome hammer is wearable.

4.Simple structure, and it is mainly including frame, rotor, and impact plate. The frame can be opened quickly by jack device in order to change spare parts and maintain.

5.The rotor and main shaft is connected by the Clamping Sets, which is easy for maintenance.

High crushing efficiency: grate plate design, rigid hard extrusion crushing, making the fine crushing efficiency greatly improved.

Environmental and energy saving: high speed and fast operation , save electricity and reduce consumption.

Wear-resistant parts durable: more durable with wear-resistant parts material.

Low maintenance cost: compared with traditional pulverizer, energy saving is better, stable operation, maintenance cost is lower.

Impact crushers use impact energy to break materials. When working, driven by the motor, the rotor rotates at high speed. When the material enters the blow bar action area, it is crushed by impact with the blow bar on the rotor, thrown to the impact device for grinding again, and bounces back from the impact lining. It goes to the plate hammer action area for re-crushing, and this process is repeated until the material is crushed to the required particle size and discharged from the discharge port. Adjusting the gap between the impact frame and the rotor can change the material discharge particle size and shape.

Model | Size of rotor (mm) | Feed opening (mm) | Max. feed size (mm) | Capacity (t/h) | Power of Motor (kW) | Weight (t) | Overall Dimensions (mm) |

PF1010 | Φ1040×1000 | 510×1040 | 200 | 50-90 | 75(100) | 12.5 | 2455×2090×2800 |

PF1210 | Φ1260×1050 | 465×1155 | 250 | 70-130 | 110(150) | 16 | 2582×2052×2810 |

PF1214 | Φ1260×1400 | 465×1485 | 300 | 90-180 | 132(175) | 18.5 | 2582×2410×2810 |

PF1315 | Φ1280×1500 | 700×1540 | 300 | 120-250 | 200(270) | 21 | 2930×2765×3053 |

*The output will vary according to different materials, feed particle size and other factors

Save Time! Get A Detailed Quotation Quickly.